M 5

M 6

M 8

M 10

M 12

M 16

5,5

6,5

8,5

10,5

12,5

17,0

7

10

15

30

50

100

16

22

27

32

40

M 8

M 10

M 12

M 16

M 20

A

l

3

d

4

R

2 - 5

6 + 8

10

12 + 14

16 + 18

28

36

40

45

48

20

25

32 + 36

50

56

60

QUICKFINDER

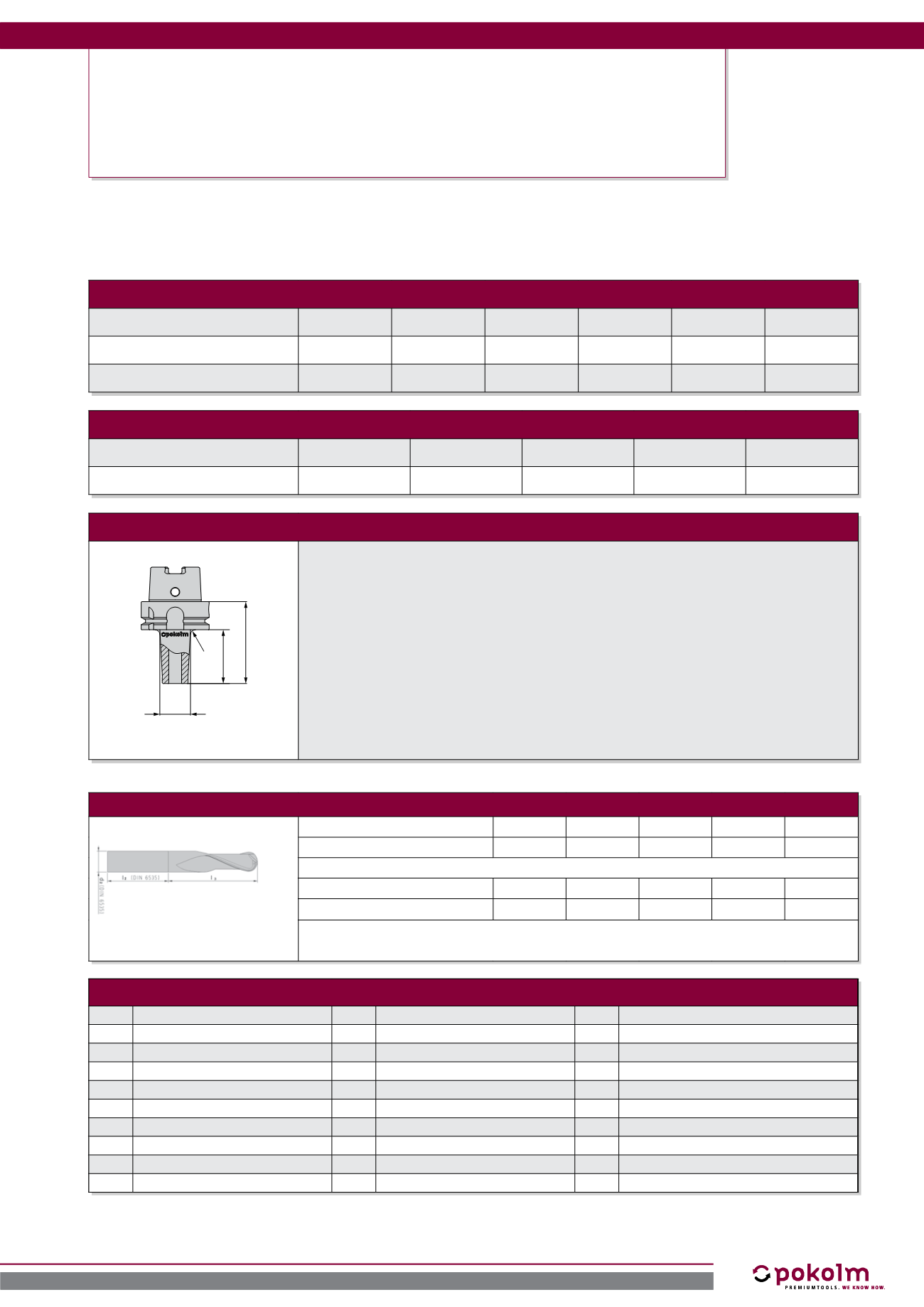

The arbor dimensions d4 and l3 (see illustration at left) are calculated up to the theoreti-

cal point of intersection between arbor taper and collar.

Please take the transition radius R (5-8 mm depending on arbor type) into account for

practical use.

Thread size

Pilot diameter in mm

diam. of shank (DIN 6535) d

2

h

5

diam. of shank (DIN 6535) d

2

h

5

Length fit zone in mm

Fixing screw

length of shank (DIN 6535) l

2

length of shank (DIN 6535) l

2

incorporated insert

toric tool

dense antivibration material

clamping flat

arbors with zero reach

7° positive axial rake angle

DUOPLUG

®

shim

concave moulding

internal coolant supply

working depth

Solid Carbide

especially suitable f. non-ferr. materials

suitable for high-speed machining

chamfer

on request

wet machining possible

2-point contact milling

stock item, subject to confirmation

dry machining possible

wet machining required

available as long as stock lasts

for direct spindle mounting

dry machining required

stainless- acid- and heat resistant

long series

balance grade

Starting torque in Nm

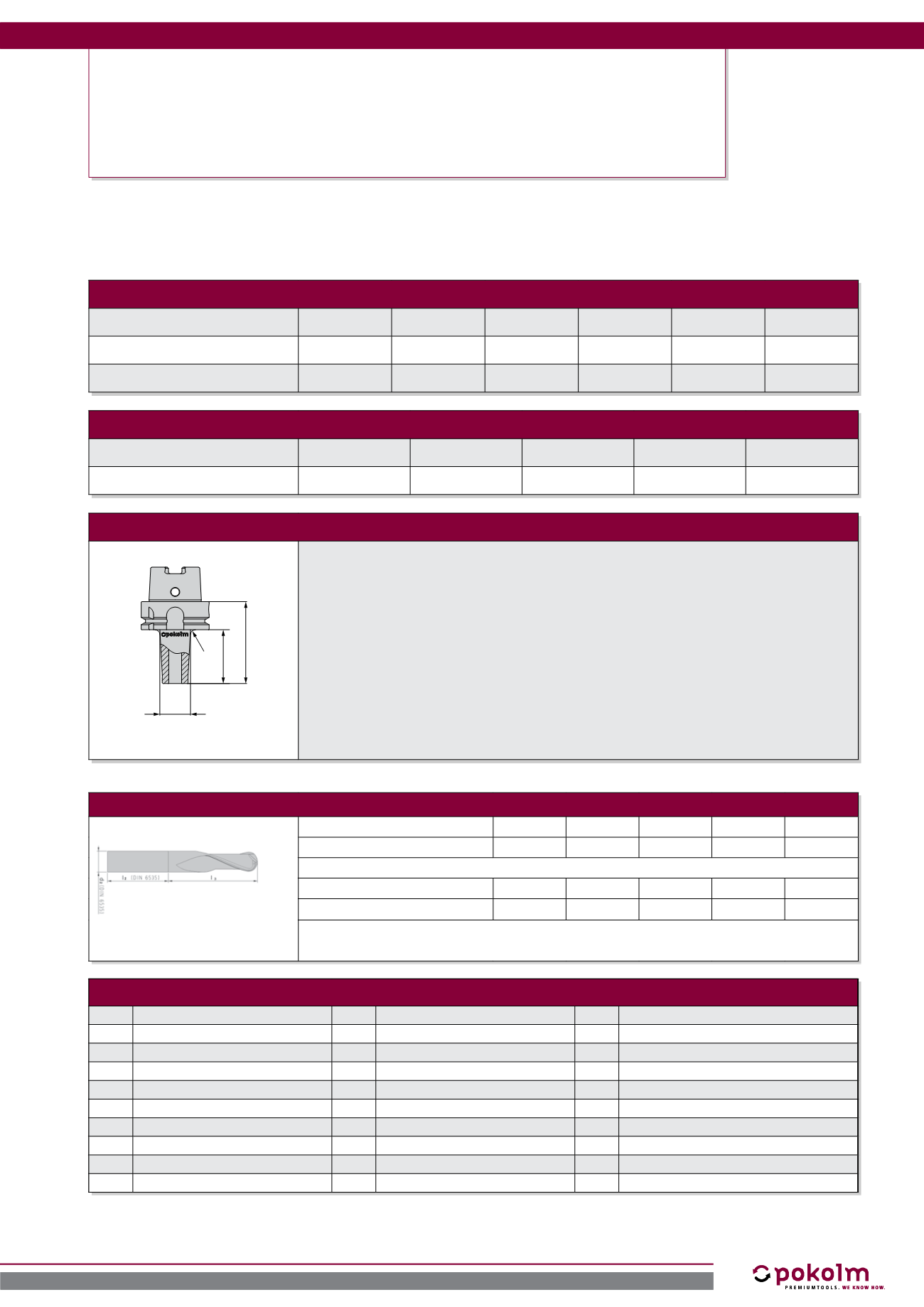

*this usable length appears through deduction of the DIN-shank-length (l2 according to DIN 6535) from the overall

length l1 of the end mill or of the solid carbide adapters. See table above.

Fit zone diam. of threaded shank end mill bodies:

Thread sizes for Shell-type arbors:

Theoretical d4 and l3:

Theoretical usable end mill length of Solid carbide end mills in mm*:

Features:

+2

- 0

+2

- 0

163

Quickfinder