159

Page

Page

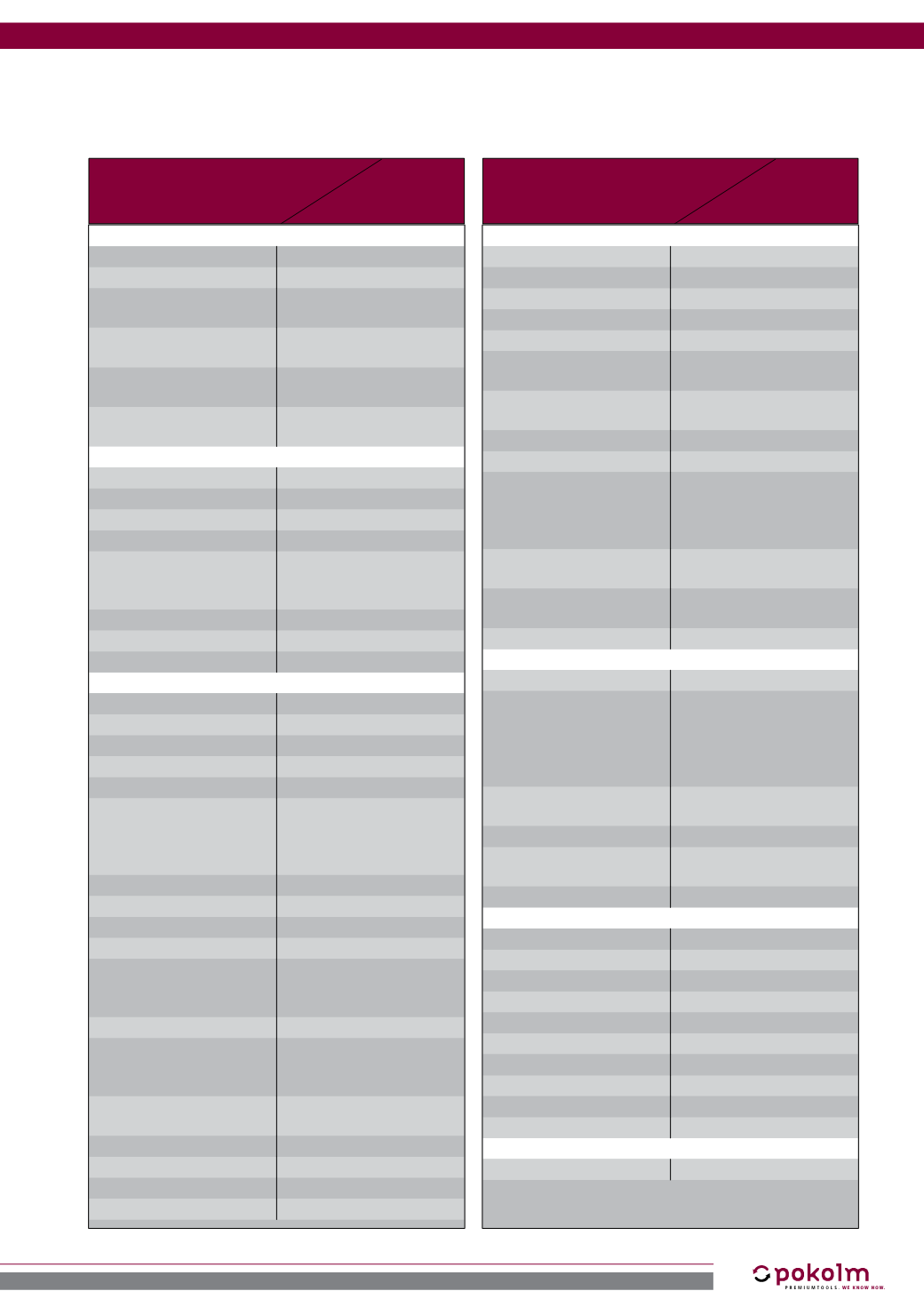

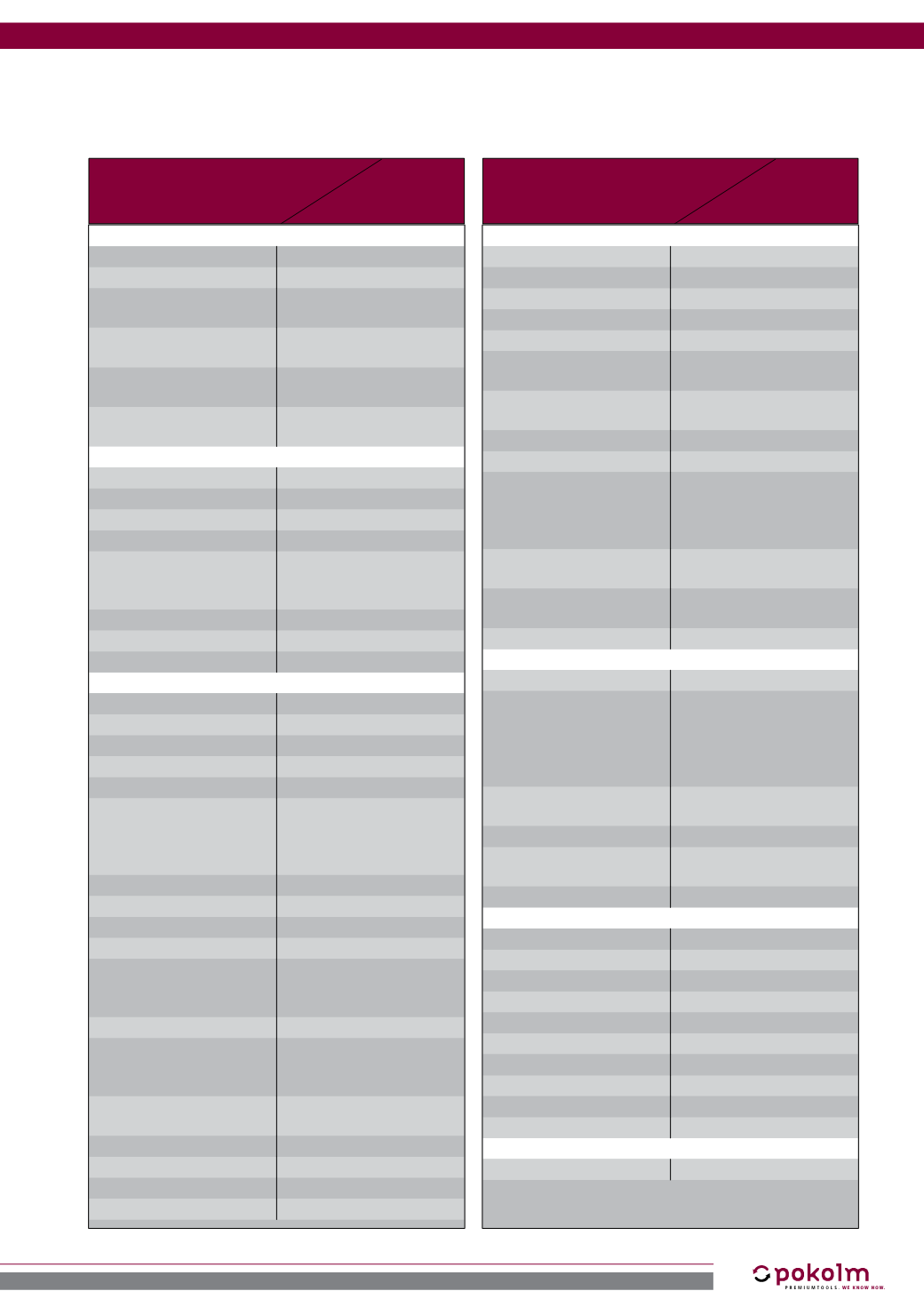

ALPHABETICAL INDEX

INDEX

A

additional rigidity

approach angle

arbors, for shell-type milling

cutters

Arbors, for threaded shank

end mills

arbors for thread connec-

tions

assembling instructions,

DuoPlug®

B

balance error

balancing

balancing grade

ball nose

bore diameter

,

BT 30

BT 40

BT 50

C

centering arbor

centrifugal force

chamfer

clamping flats

coatings

collet chucks

,

,

combination possibilities

compensation mass

component quality

concentricity

,

,

,

coolant supply

,

,

,

,

coolant supply, internal

coolant supply tubes, HSK

,

,

,

,

,

,

Coolcap

corner radius

corrective drill hole

customized arbors

cutting speed

D

definition

dense antivibration material

DIN/ISO 1940

DIN 2080

DIN 6499-B

DIN 69 871

,

,

,

,

DIN 912

,

,

,

DIN 914

direct spindle mounting

,

Drill Chuck

,

,

,

,

drive blocks

,

,

,

DuoPlug®

,

,

,

DuoPlug®, assembling

E

eccentricity

end mills

,

,

,

,

,

,

,

,

,

ER 20

ER-collets

extension

,

,

,

,

extra hard coating

F

fatigue strength

feed rate

fine thread

finishing

,

,

finishing operations

FINWORX

fit zone

,

flange contact surface

formulas

frequency

H

heat resistance