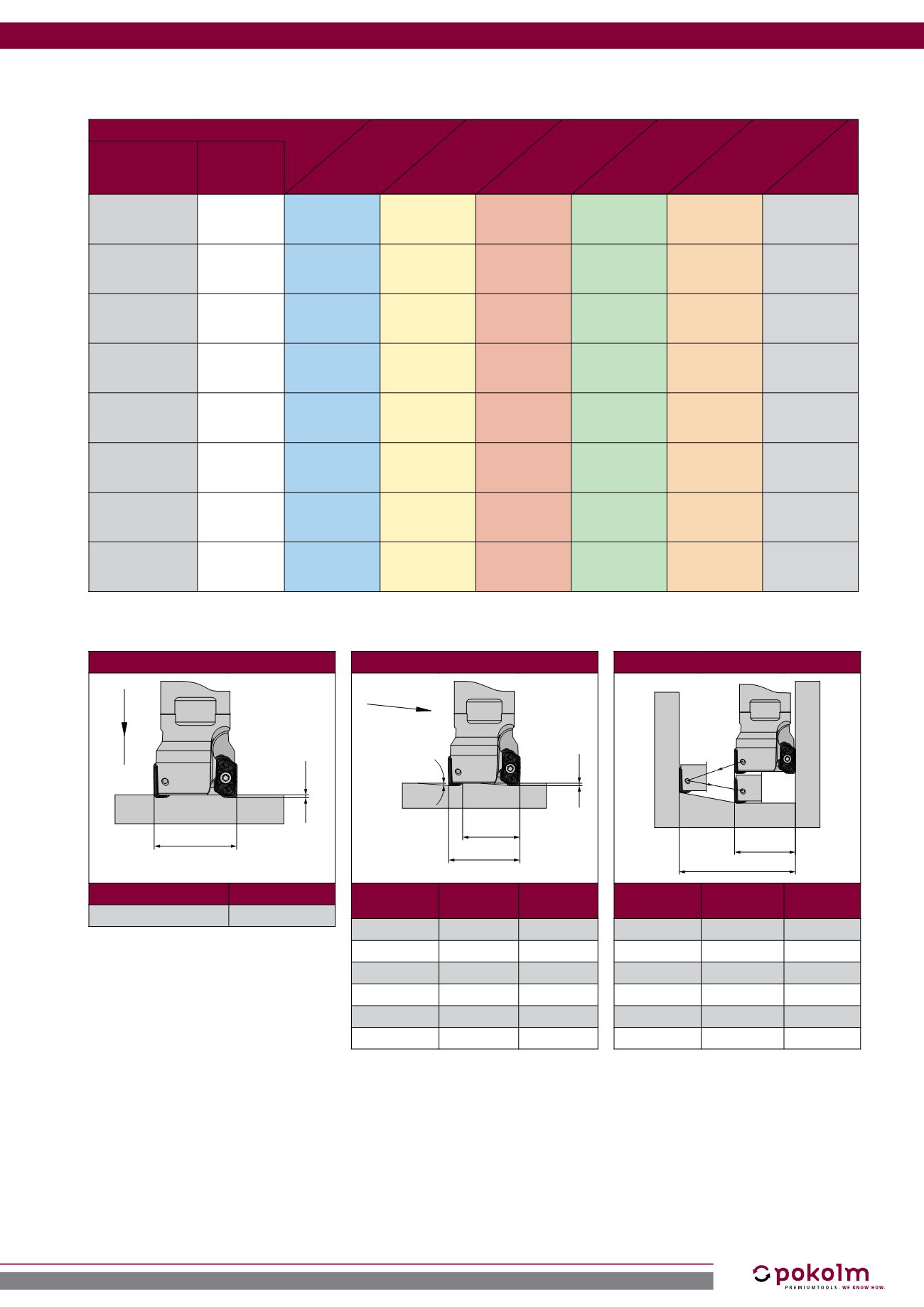

45

major application

minor application

roughing

pre-finishing

finishing

Plunging

d

1

X

Cutter diam. d1

X

max

16-52

2.5

Ramping

α

d

1

Y

X

Cutter diam.

d1

α

°

y

16

<24,5

5.3

20

<14,5

9.3

25

<8

14.3

32

<5

21.3

42

<3

31.3

52

<2,5

41.3

Helix

D min max

d

1

Cutter diam.

d1

D

min

D

max

16

21.3

32

20

29.3

40

25

39.3

50

32

53.3

64

42

73.3

84

52

93.3

104

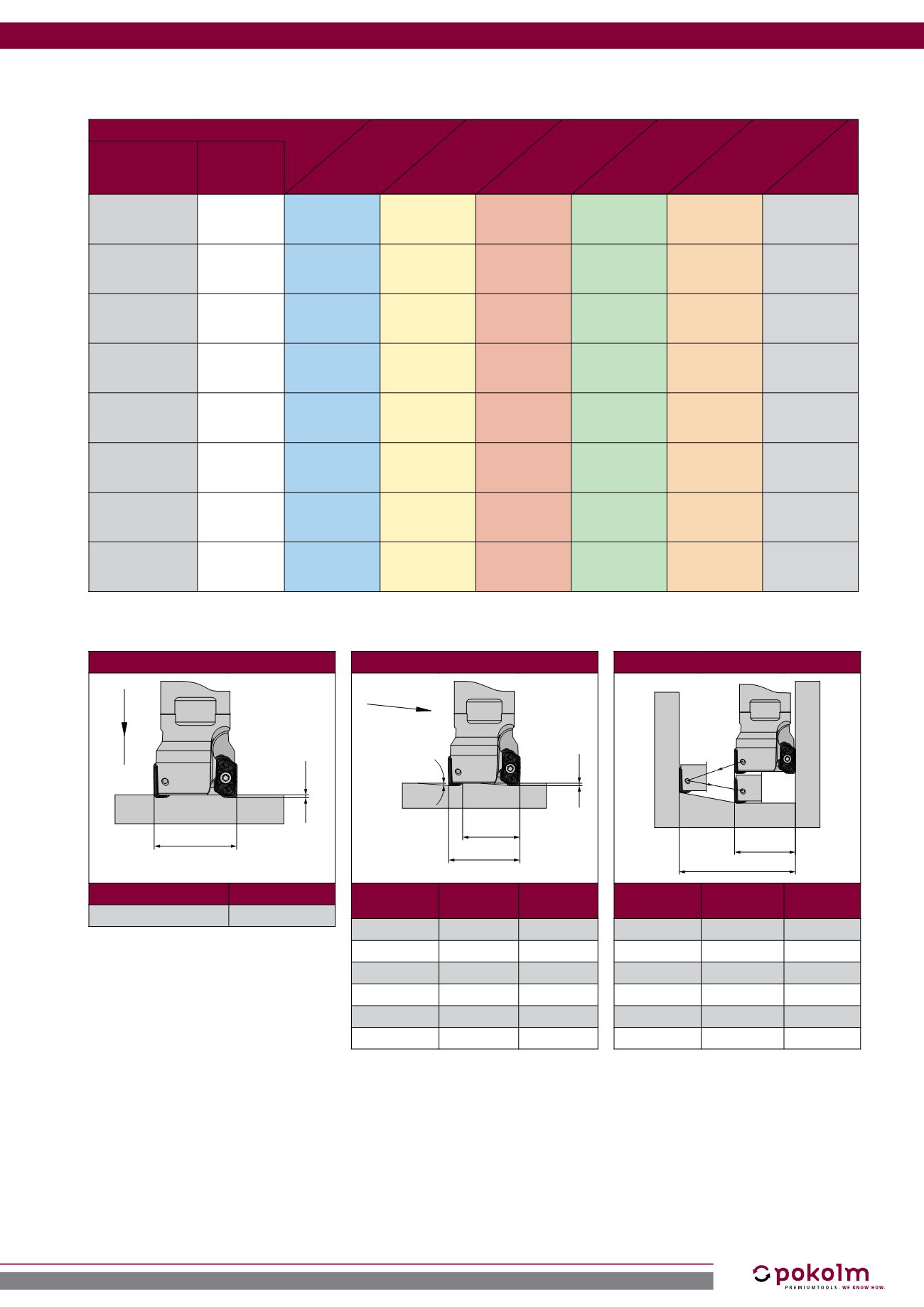

Extended operation data

Material

steel

stainless steel

cast iron

non-ferrous

materials

high-temperature

alloys

hardened steel

Quality

Coating

Application

K10 polished

roughing

pre finishing

finishing

-

-

-

100

450

800

100

450

800

100

450

800

-

-

HSC 05 PVFN

roughing

pre finishing

finishing

120

160

200

120

160

200

-

-

100

150

200

100

150

200

-

-

-

80

150

220

40

130

220

40

130

220

P40 PVGO

roughing

pre finishing

finishing

100

150

200

100

150

200

160

205

250

90

110

130

90

110

130

110

135

160

110

130

150

110

130

150

120

150

180

-

60

80

100

60

80

100

80

100

120

-

M40 PVST

roughing

pre finishing

finishing

80

140

200

100

150

200

-

80

130

180

100

155

210

120

185

250

-

-

30

55

80

40

65

90

60

90

120

-

M35 PCTC

roughing

pre finishing

finishing

-

110

155

200

120

175

230

160

220

280

-

-

30

65

100

40

75

110

60

100

140

-

K10 PVTi

roughing

pre finishing

finishing

-

-

-

100

450

800

100

450

800

100

450

800

-

-

35

68

100

-

-

35

143

250

K10 PVDiaN

roughing

pre finishing

finishing

-

-

-

100

450

800

100

450

800

100

450

800

-

-

PCD uncoated

roughing

pre finishing

finishing

-

-

-

200

400

600

400

600

800

600

800

1000

-

-

Cutting speed (Vc in m/min)