47

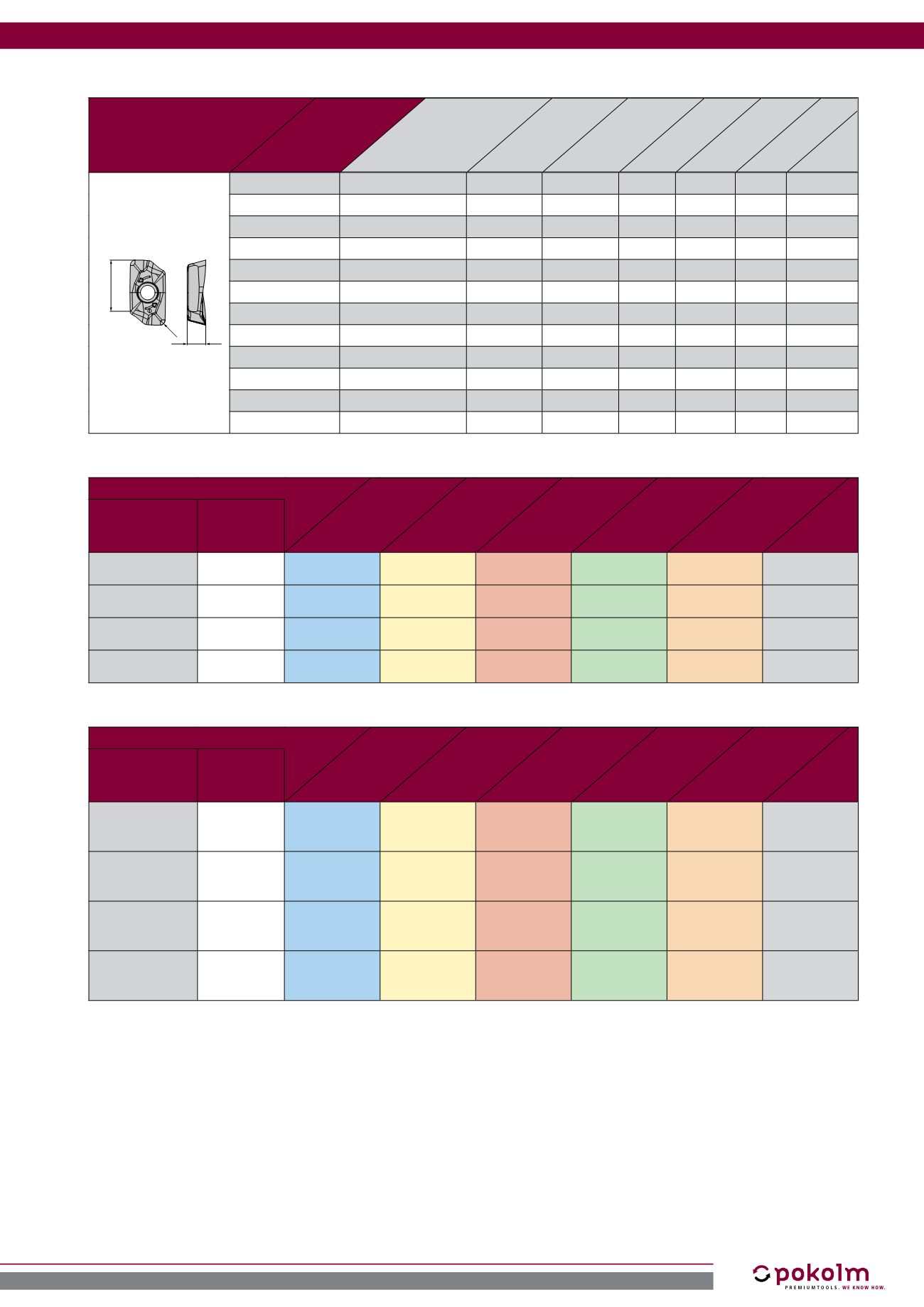

major application

minor application

roughing

pre-finishing

finishing

Material

steel

stainless steel

cast iron

non-ferrous

materials

high-temperature

alloys

hardened steel

Quality

Coating

Feed per

tooth | d.o.c.

K10 polished

f

z

(mm)

a

p

(mm)

-

-

-

0,08-0,35

0,1-14

-

-

P40 PVGO

f

z

(mm)

a

p

(mm)

0,1-0,5

0,2-14

-

0,1-0,5

0,2-14

-

-

-

K10 PVTi

f

z

(mm)

a

p

(mm)

0,1-0,4

4-14

-

0,1-0,4

0,2-14

-

-

-

M40 PVST

f

z

(mm)

a

p

(mm)

-

0,08-0,5

0,1-14

-

-

0,08-0,25

0,1-14

-

Material

steel

stainless steel

cast iron

non-ferrous

materials

high-temperature

alloys

hardened steel

Quality

Coating

Application

K10 polished

roughing

pre finishing

finishing

-

-

-

100

450

800

100

450

800

100

450

800

-

-

P40 PVGO

roughing

pre finishing

finishing

100

150

200

100

150

200

160

205

250

-

110

130

150

110

130

150

120

150

180

-

-

-

K10 PVTi

roughing

pre finishing

finishing

130

170

210

150

185

220

-

-

150

175

200

150

175

200

150

200

250

-

-

-

M40 PVST

roughing

pre finishing

finishing

-

80

130

180

100

155

210

120

185

250

-

-

30

55

80

40

65

90

60

90

120

-

Feed per tooth (fz) | d.o.c. (ap)

Cutting speed (Vc in m/min)

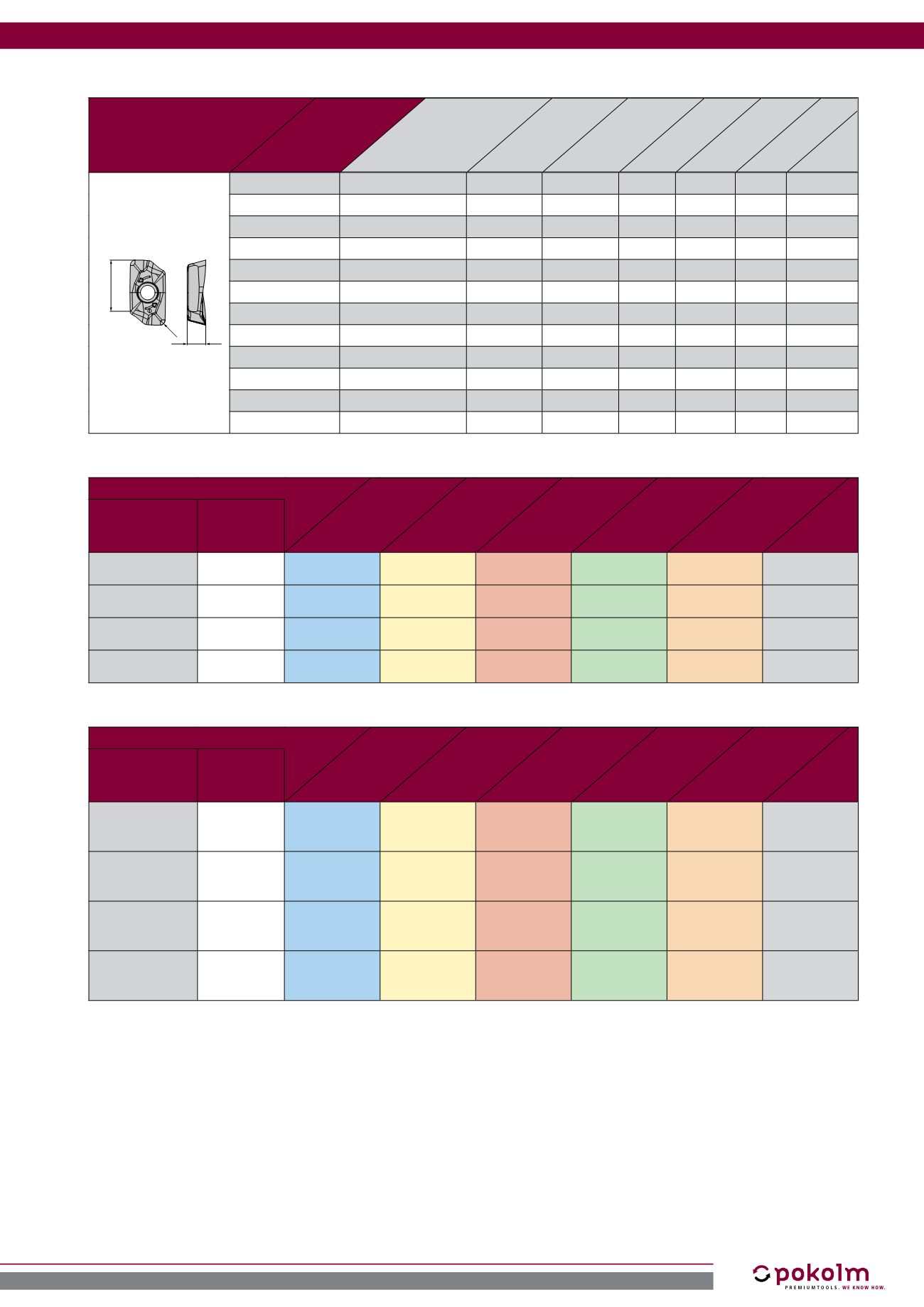

Indexable inserts

Catalogue no.

DIN Specification

Carbide Grade

Coating

l

s

r

M

s

l

r

05 68 820

XDHT 155210

K10

polished

15

5.2

1

M 3.5

05 68 848 XDMT 155210 ER

P40

PVGO

15

5.2

1

M 3.5

05 68 862 XDMT 155210 ER

K10

PVTi

15

5.2

1

M 3.5

05 68 896 XDMT 155210 ER

M40

PVST

15

5.2

1

M 3.5

05 68 820 R20 XDHT 155230 FR

K10

polished

15

5.2

2

M 3.5

05 68 896 R20 XDMT 155220 ER

M40

PVST

15

5.2

2

M 3.5

05 68 820 R30 XDHT 155230 FR

K10

polished

15

5.2

3

M 3.5

05 68 896 R30 XDMT 155230 ER

M40

PVST

15

5.2

3

M 3.5

05 68 820 R40 XDHT 155240 FR

K10

polished

15

5.2

4

M 3.5

05 68 896 R40 XDMT 155240 ER

M40

PVST

15

5.2

4

M 3.5

05 68 820 R50 XDHT 155250 FR

K10

polished

15

5.2

5

M 3.5

05 68 896 R50 XDMT 155250 ER

M40

PVST

15

5.2

5

M 3.5