37

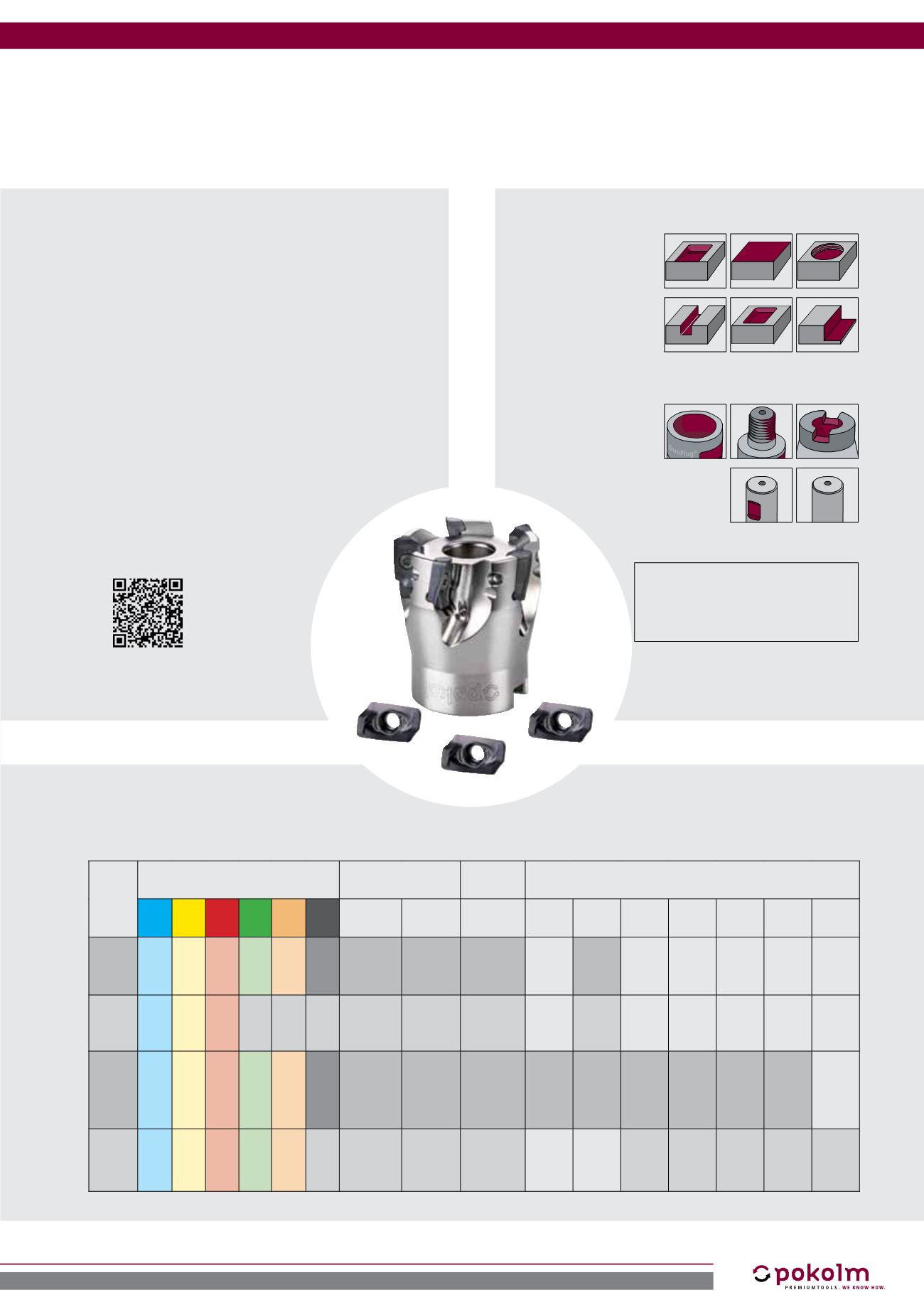

major application

minor application

roughing

pre-finishing

finishing

P M

K

N S

H

0.4

0.8

1.0

2.0

3.0

4.0

5.0

HP-S

0.05 - 0.3 0.3 - 2.0

6.2

-

HSC05

S

- - -

0.02 - 0.17 0.1 - 3.0

6.9

-

P40

-

-

-

-

-

M

0.05 - 0.35 0.1 - 9.0

10

K10

K10,

HSC05,

P40,

M40,

M35

K10,

HSC05,

P40,

PKD,

M40

K10,

M40

K10,

M40

K10,

M40

-

L

-

0.08 - 0.5 0.1 - 14

15

-

-

K10,

P40,

M40

K10,

M40

K10,

M40

K10,

M40

K10,

M40

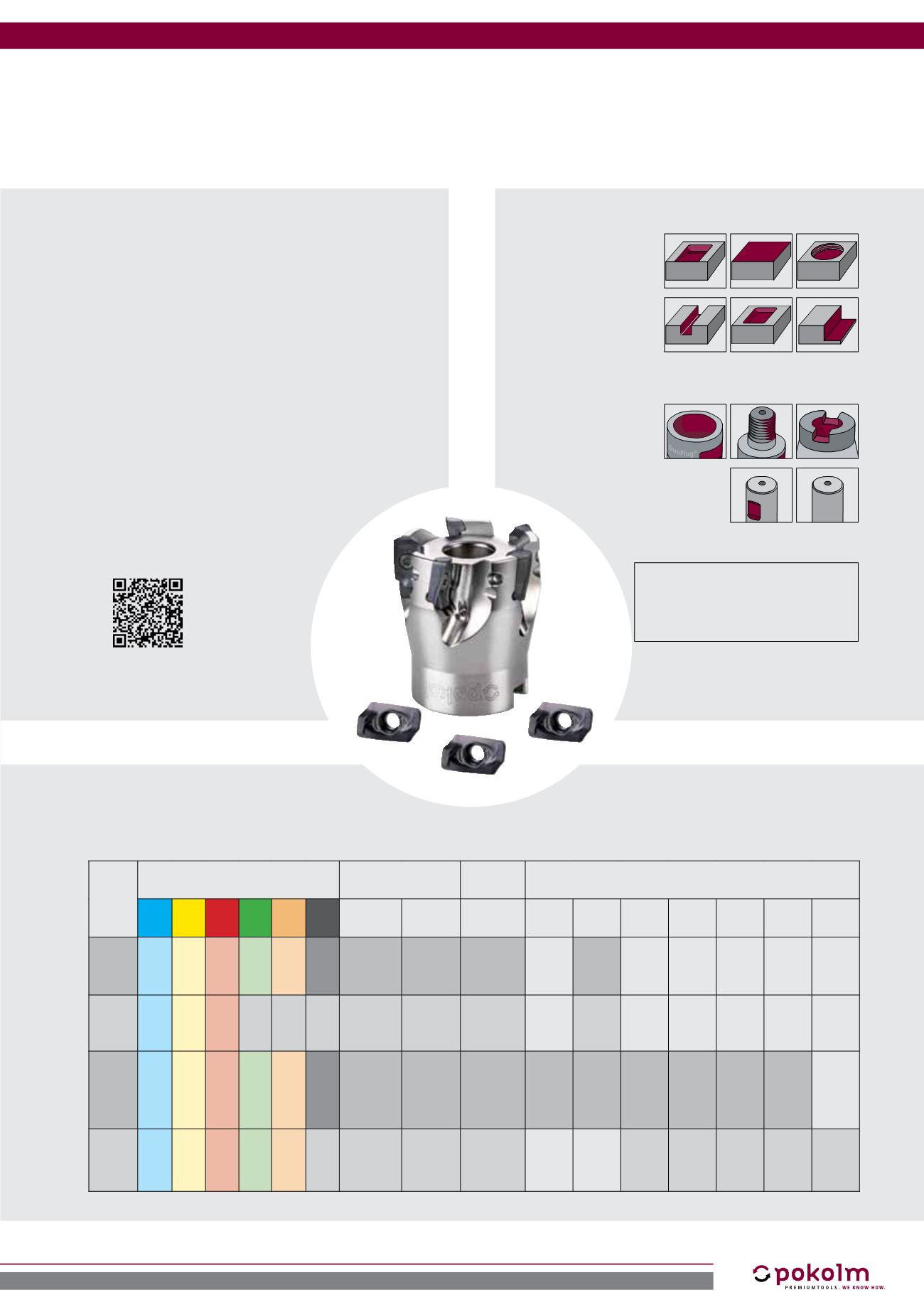

Machining types

Properties

Cutting materials

Sizes

Page

Connection types

Practical video

SLOTWORX

®

SQUARE SHOULDER FACE MILLING

AND SLOTTING CUTTER BODIES

With highly modern cutting edge geometry for universal applications

uu

SLOTWORX

®

M / zero reach adapters

DuoPlug SK50 / 1.2344 ESU

48 HRC / X40CrMoV

uu

Universal use options: Roughing and finishing

of steel, aluminium, graphite, plastic, hardened

materials, cast iron and stainless as well

as high-temperature resistant materials

uu

Optimised coolant supply up to the

cutting edge

uu

Integrated finishing land achieves

outstanding surface qualities

uu

Corner radii from 0.4 - 5 mm

HP-S: diam. 10 - 32 mm 38

S: diam. 10 - 20 mm 40

M: diam. 16 - 52 mm 42

L: diam. 25 - 100 mm 46

Size

ISO Standard

feed per tooth | d.o.c.

length

l (mm)

a

p

(mm)

f

z

(mm)

Size, radius (mm), Carbide grade