79

major application

minor application

roughing

pre-finishing

finishing

Material

steel

stainless steel

cast iron

non-ferrous

materials

high-temperature

alloys

hardened steel

Quality

Coating

Feed per

tooth | d.o.c.

HSC 05 PVTi

f

z

(mm)

a

p

(mm)

0,1-0,2

0,1-0,3

0,1

0,1

0,1-0,3

0,1-0,5

0,1-0,2

0,1-0,4

-

0,1-0,12

0,1-0,15

P40 PVTi

f

z

(mm)

a

p

(mm)

0,1-0,3

0,1-0,5

-

-

-

-

-

P40 PVSR

f

z

(mm)

a

p

(mm)

0,1-0,3

0,1-0,7

-

0,1-0,3

0,1-0,5

-

-

0,1-0,15

0,1-0,2

P40 PCSR

f

z

(mm)

a

p

(mm)

0,05-0,45

0,05-0,7

-

0,1-0,4

0,05-0,65

-

-

-

K10 PVTi

f

z

(mm)

a

p

(mm)

0,1

0,1

0,1

0,1

0,1-0,3

0,1-0,5

0,1-0,15

0,1-0,3

0,1-0,12

0,1-0,15

K10 polished

f

z

(mm)

a

p

(mm)

-

-

-

0,1-0,3

0,1-0,7

-

-

K10 PVDiaN

f

z

(mm)

a

p

(mm)

-

-

-

0,1-0,3

0,1-0,7

-

-

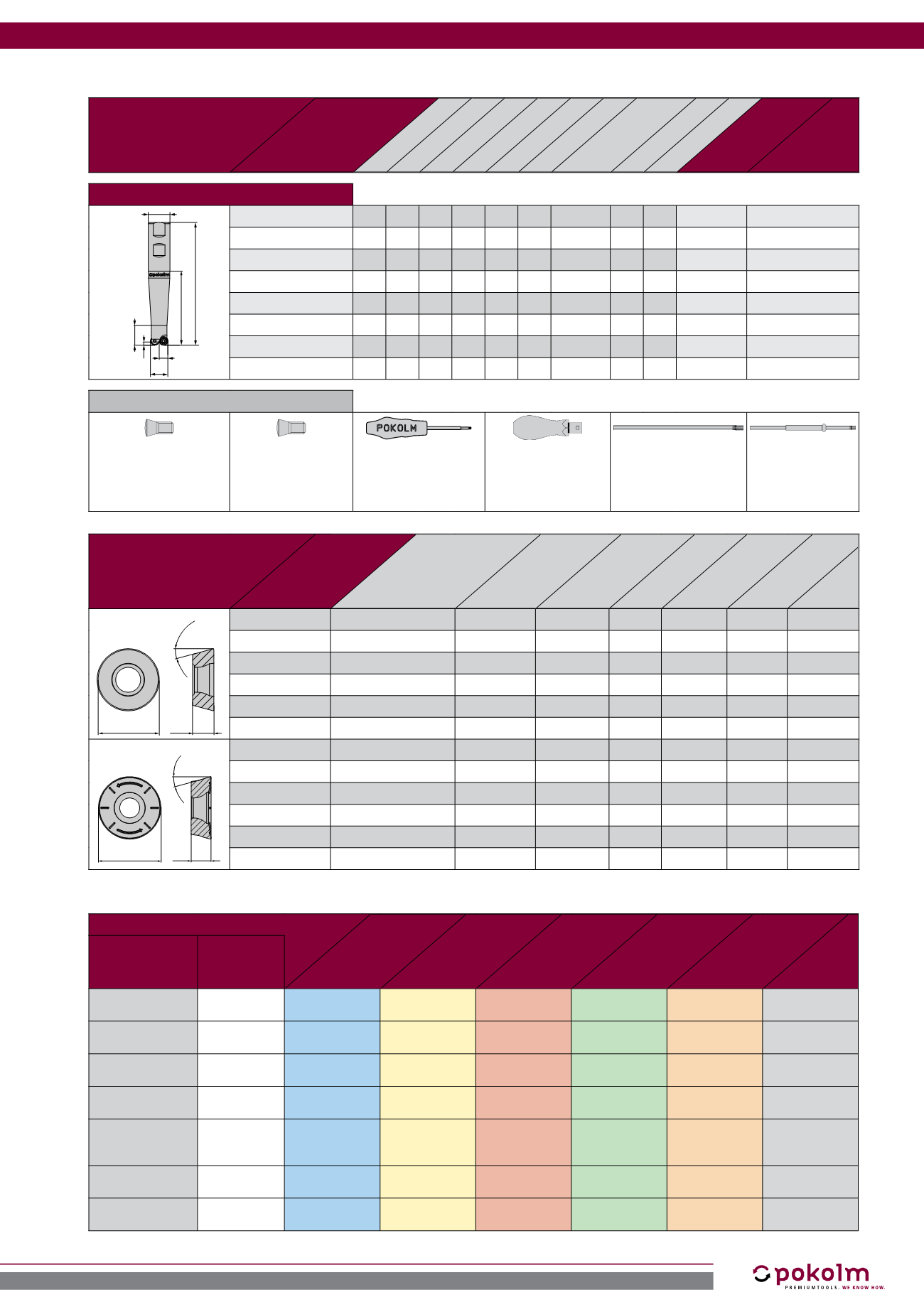

Indexable inserts

Catalogue no.

DIN Specification

Carbide Grade

Coating

d

s

r

M

s

15°

d

01 07 835 RDHX 07T1 M0T

HSC 05

PVTi

7

1.99

3.5

M 2.5

01 07 840 RDHX 07T1 M0T

P40

PVTi

7

1.99

3.5

M 2.5

01 07 842 RDEX 07T1 M0T

P40

PVSR

7

1.99

3.5

M 2.5

01 07 8042 RDEX 07T1 M0T

P40

PCSR

7

1.99

3.5

M 2.5

01 07 860 RDHX 07T1 M0T

K10

PVTi

7

1.99

3.5

M 2.5

s

15°

d

01 07 831P RDHX 07T1 M0E

K10

polished

7

1.99

3.5

M 2.5

01 07 880 D RDHX 07T1 M0E

K10

PVDiaN

7

1.99

3.5

M 2.5

01 07 880 RDHX 07T1 M0E

K10

PVTi

7

1.99

3.5

M 2.5

Feed per tooth (fz) | d.o.c. (ap)

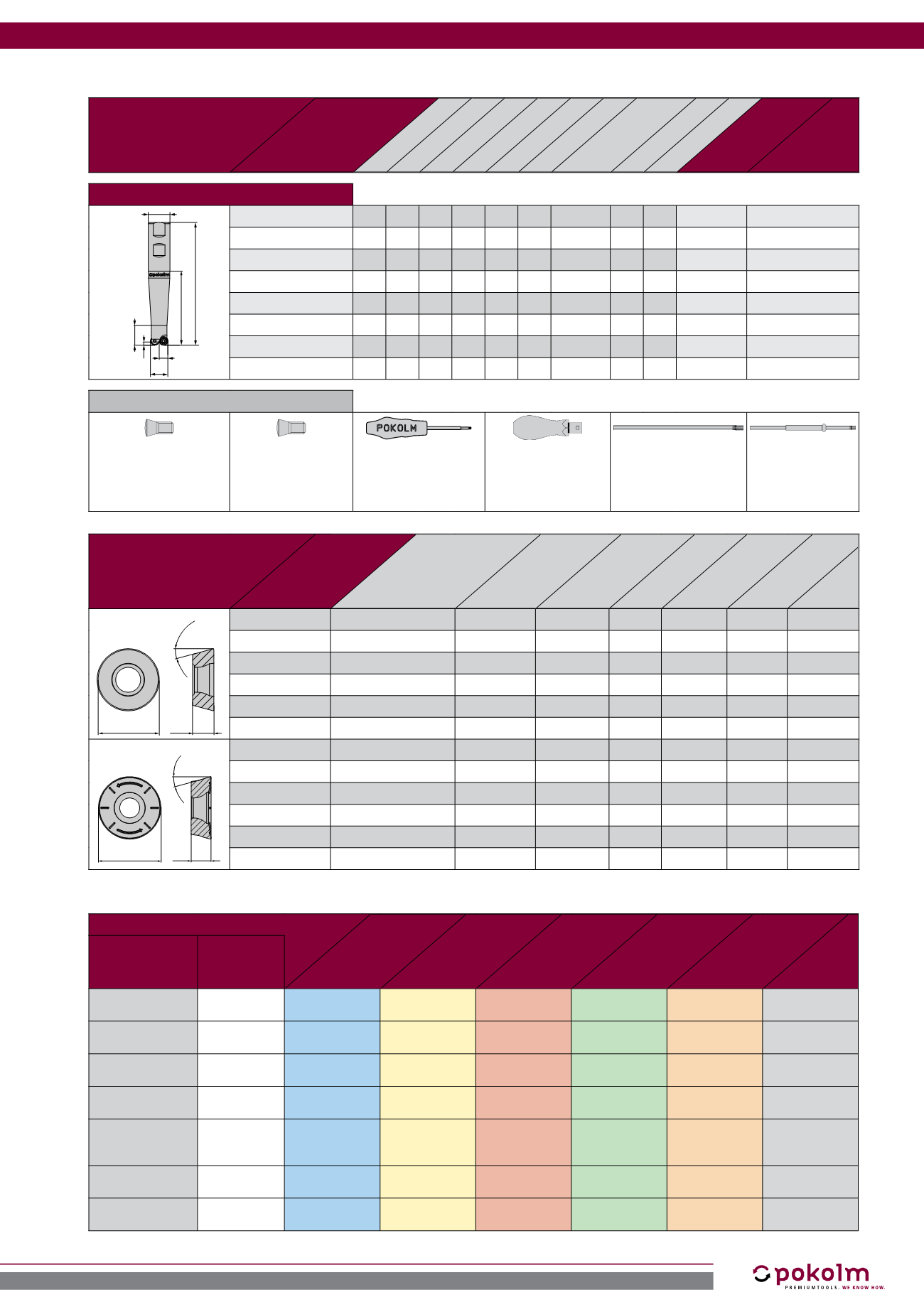

Milling cutter bodies

Catalogue no.

Accessories

Features

d

1

d r

l

3

l

2

l

1

d

2

d

3

z

End mill bodies with plain shanks and flats

l

1

l

4

d

1

d

l

3

d

2

l

2

40 12 100 12 7 3.5 40 -

19.5 diam. 16 -

2 B, C, D, E, F

60 12 100 12 7 3.5 60 -

19.5 diam. 16 -

2 B, C, D, E, F

80 12 100 12 7 3.5 80 -

19.5 diam. 16 -

2 B, C, D, E, F

30 15 100 15 7 3.5 30 1.2 19.5 diam. 12 -

3 A, C, D, E, F

Accessories

25 500

Torx screw

A > Page

25 500 K

Torx screw

B > Page

07 500

Torx-screwdriver

C > Page

TV 04-1

Screwdriver torque

Vario®-S with window

scale, D > Page

T7 500

Torx interchangeable bit

for Torque Vario®

E > Page

T7 502, Torx Magic-

Spring compatible bit

f. Torque Vario®

F > Page