114

latest items!

available as long as stock lasts

on request

stock item, subject to confirmation

Material

steel

stainless steel

cast iron

non-ferrous

materials

high-temperature

alloys

hardened steel

Quality

Coating

Application

HSC 05 PVTi

roughing

pre finishing

finishing

-

150

275

400

150

275

400

-

-

100

150

200

100

150

200

150

225

300

200

275

350

-

200

500

800

100

450

800

-

-

35

143

250

35

143

250

P40 PVTi

roughing

pre finishing

finishing

100

160

220

100

175

250

-

-

-

-

-

-

P25 PVTi

roughing

pre finishing

finishing

100

200

300

100

125

150

150

250

350

-

-

130

150

170

150

200

250

-

-

-

K10 PVTi

roughing

pre finishing

finishing

-

-

140

220

300

-

-

120

150

180

150

175

200

150

175

200

150

200

250

100

450

800

100

450

800

100

450

800

35

43

50

35

43

50

35

43

50

-

35

108

180

-

K10 polished

roughing

pre finishing

finishing

-

-

-

100

450

800

100

450

800

100

450

800

-

-

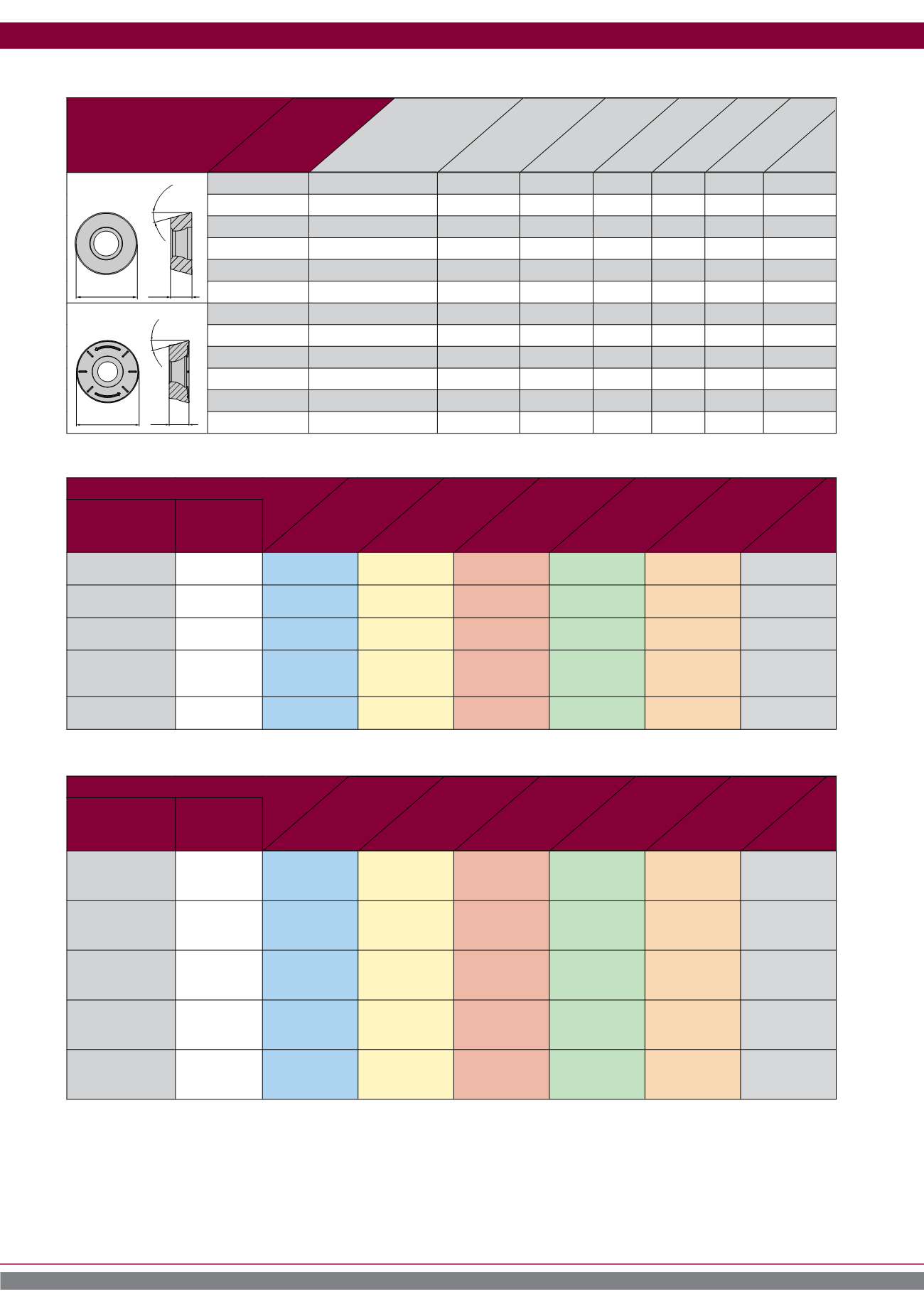

Indexable inserts

Catalogue no.

DIN Specification

Carbide Grade

Coating

d

s

r

M

s

15°

d

06 20 835 RDMX 2006 M0T

HSC 05

PVTi

20

6

10

M 4.5

06 20 840 RDMX 2006 M0T

P40

PVTi

20

6

10

M 4.5

06 20 850 RDMX 2006 M0T

P25

PVTi

20

6

10

M 4.5

06 20 860 RDMX 2006 M0T

K10

PVTi

20

6

10

M 4.5

s

15°

d

06 20 831P

RDHT 2006 M0T

K10

polished

20

6

10

M 4.5

06 20 880

RDHT 2006 M0T

K10

PVTi

20

6

10

M 4.5

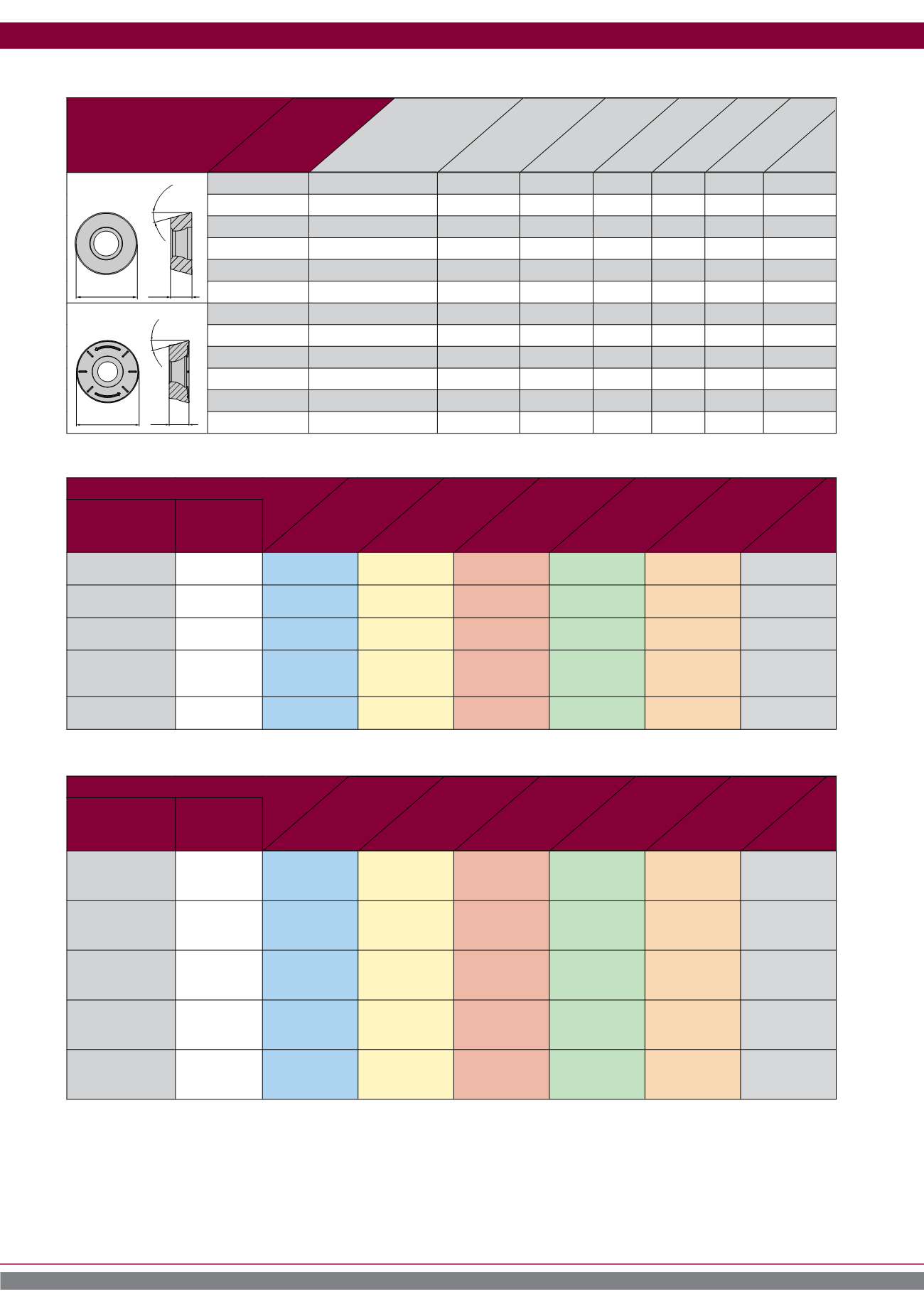

Feed per tooth (fz) | d.o.c. (ap)

Material

steel

stainless steel

cast iron

non-ferrous

materials

high-temperature

alloys

hardened steel

Quality

Coating

Feed per

tooth | d.o.c.

HSC 05 PVTi

f

z

(mm)

a

p

(mm)

0,25-0,32

0,2-1,1

0,15

0,1

0,25-0,6

0,2-4

0,25-0,42

0,2-5

-

0,2-0,3

0,2-1,1

P40 PVTi

f

z

(mm)

a

p

(mm)

0,25-1,2

0,2-5

-

-

-

-

-

P25 PVTi

f

z

(mm)

a

p

(mm)

0,25-0,6

0,2-4

-

0,25-0,42

0,2-2,1

-

-

-

K10 PVTi

f

z

(mm)

a

p

(mm)

0,15

0,1

0,25-0,6

0,2-5

0,2-0,4

0,2-3

K10 polished

f

z

(mm)

a

p

(mm)

-

-

-

0,25-0,6

0,2-5

-

-

Cutting speed (Vc in m/min)

Cutters for round inserts - k0-90° Copy cutters