SHRINKING TECHNOLOGY

Induction shrinking stations and accessories

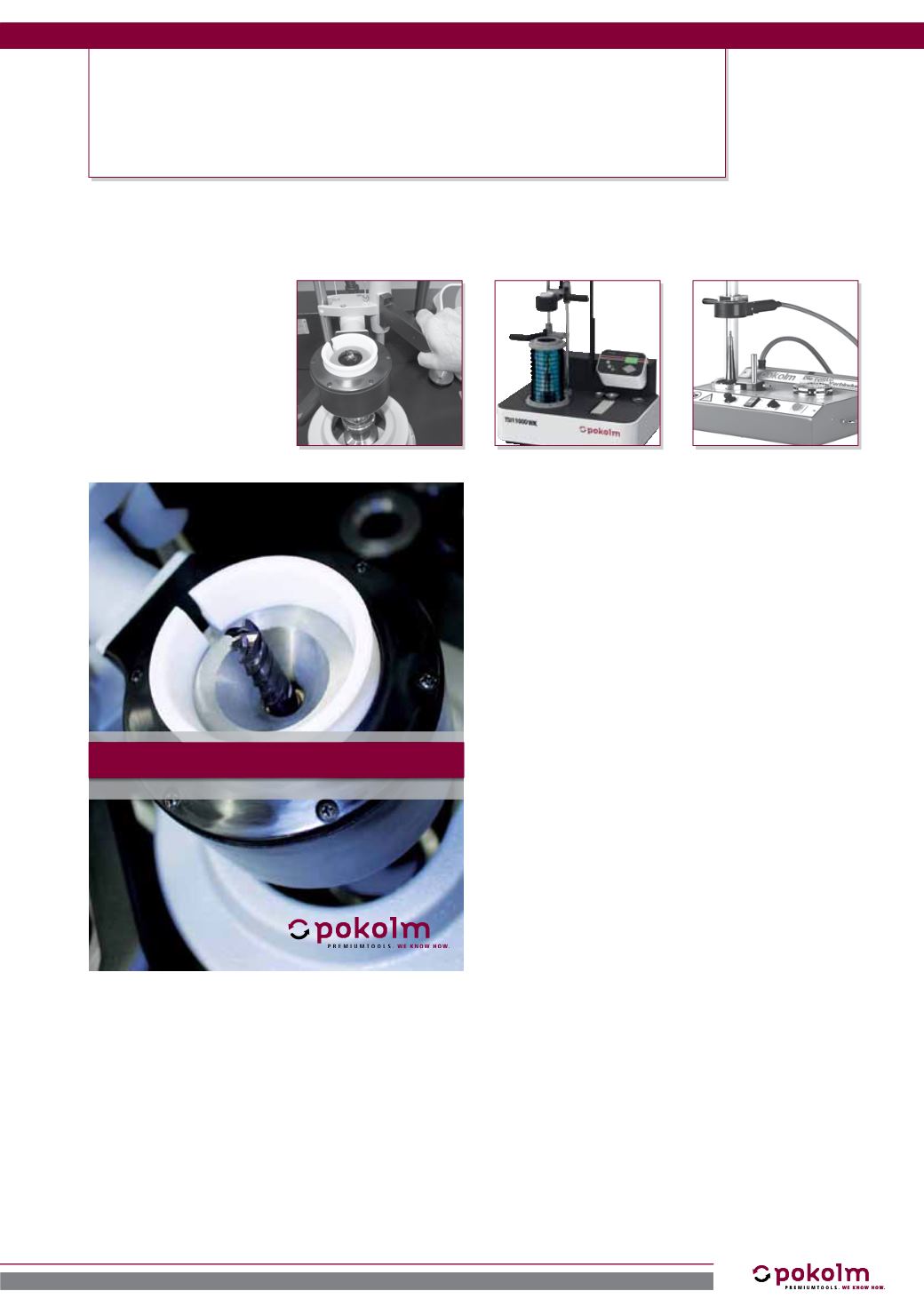

FIRST OPERATION: SHRINKING, THEN MILLING

Shrinking Technology convinces everybody compared

with conventional chucking methods from the past. What

counts? Absolute concentricity and highest precision with

extensive extended tool life. Shrinking technology offers a

safe friction-locked connection between tool and tool hol-

der and povides an increased transferable torque. And the

qualification for maximum revolutions is the best precondi-

tion for an optimum surface finish and for reducing costs

for expensive finishing processes.

Compared to coventional milling chucks, shrinking arbors

allow the use of distinctly slim adaptors for machining

components with narrow situations, which would be un-

executable with other tool-holding systems.

Pokolm offers a substantial range of tooling for shrinking

technology: several top-class Induction Shrinking Units,

shrinking arbors for all possible machine connections and

our patent-protected connection system

DUOPLUG

®

in

combination with our "zero-reach"-shrinking arbors.

(Additional information about the Pokolm

DUOPLUG

®

Sys-

tem can be found under chapter "Milling Cutter Bodies" of

this catalogue.)

INDUCTIVE SHRINKING TECHNOLOGY

201

Inductive shrinking technology