ø 5 x 1,50

ø 12 x 3,97

ø 7 x 1,99

ø 7 x 2,38

ø 10 x 3,18

ø 16 x 4,76

ø 20 x 6,00

7

-x

0

7

-x

0

7

-x

0

TECHNOLOGY OVERVIEW

MILLING CUTTER BODIES

u

u

Increased economic ef ficiency

Our seven different diameters for round inserts alone, plus numerous additional geometries and sizes – combined with

five different rake angles in our milling cutter bodies – provide optimum cutting conditions for almost every application

you can think of.

Large variaty of rake angles for every special application.

negativ rake angle for maximum stability

and smooth running

0° rake angle, the best solution for high accu-

rate contur millung and machining hardened

materials

milling cutter bodies with positive rake angles

are suitable for nearly every application, to-

gether with inserts with concave molding they

are the best solution for machining RSH mate-

rials

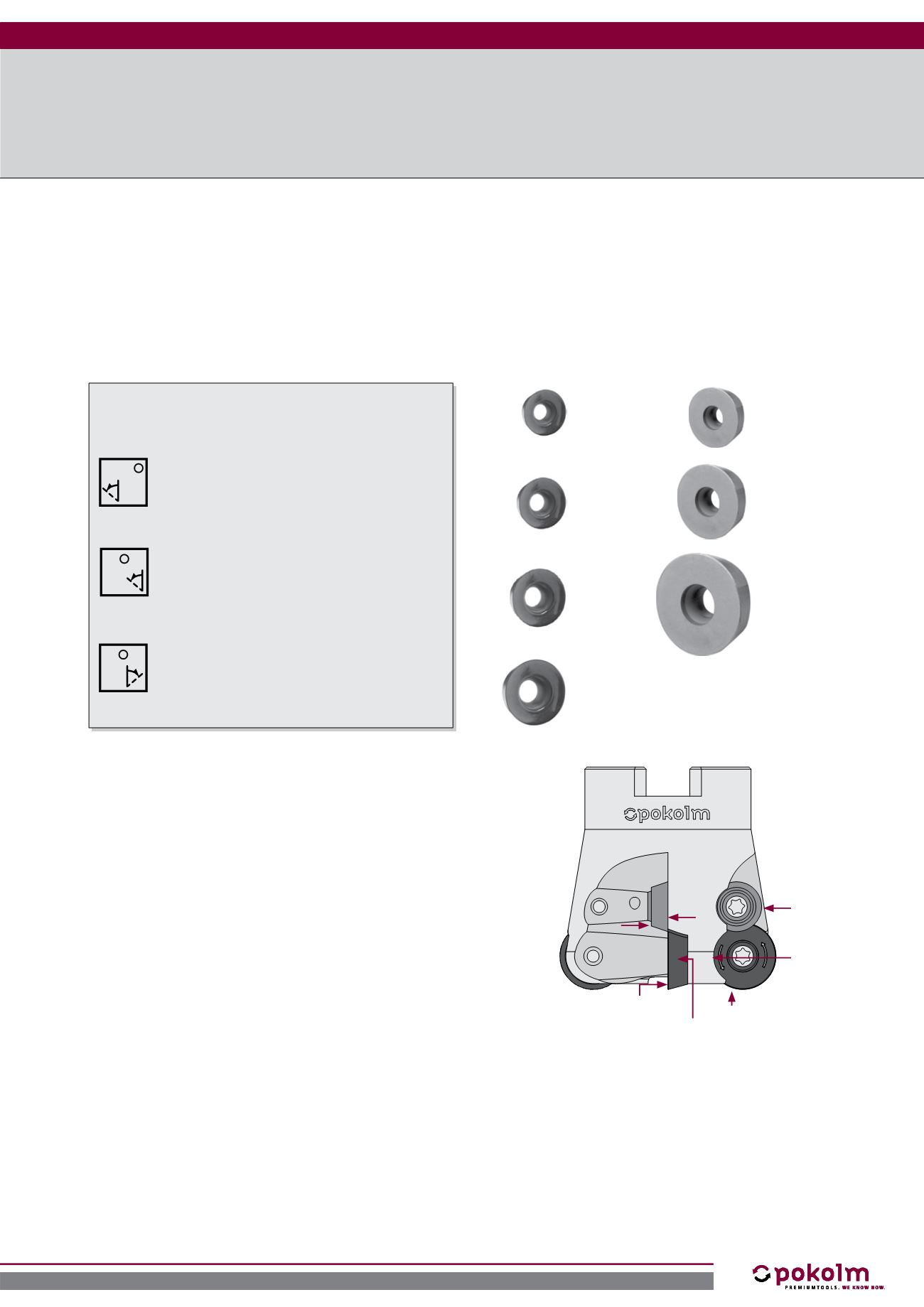

additional

(double)

clamp

support in

cutter body

retention

forces

clamping

claw

cutting pressure

cutting pressure

Torx

®

screw

Optimum load distribution

The patent-protected, specially developed insert seats in our milling cut-

ter bodies absorb all axial and radial milling forces, because the insert is

not only fixed with a Torx

®

screw, it is also supported by being embedded

into the cutter body. Thus, the cutting pressure no longer acts on the

screw alone, but is also absorbed by our milling cutter bodies.

Compared to open insert seats, our incorporated insert seats allow stron-

ger teeth, clearly improving the rigidity of our milling cutters. This results

in longer tool life and allows higher feed rates. Additional double clamps

provide excellent support, even under extreme cutting conditions.

Reduced wear

Our chip spaces were specially designed for exceptionally easy chip flow, thus protecting both body and workpiece from

damage. The supply channels for the coolant in arbors and cutter bodies are precisely coordinated with each other so

that the coolant is conducted directly onto the cutting edge even under difficult cutting conditions.

Specially selected materials and extra-hard coatings offer higher tensile strength and heat resistance, making Pokolm

tools and arbor systems unbeatable in durability and long-life-cycles.

21

Milling cutter bodies -USPs2