25

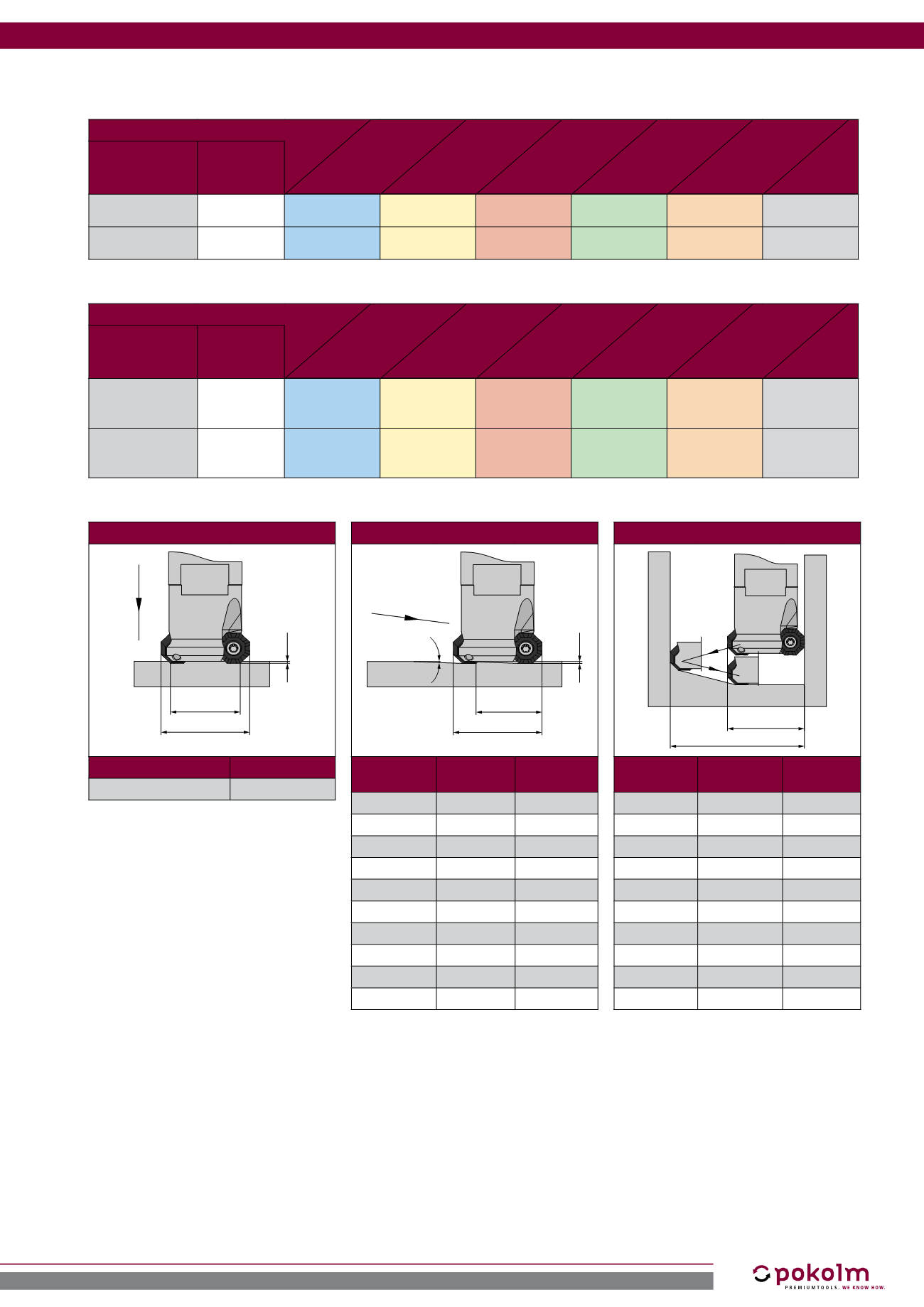

major application

minor application

roughing

pre-finishing

finishing

Material

steel

stainless steel

cast iron

non-ferrous

materials

high-temperature

alloys

hardened steel

Quality

Coating

Feed per

tooth | d.o.c.

K10 polished

f

z

(mm)

a

p

(mm)

-

-

-

0,08-0,3

0,1-3,5

-

-

P40 PVTi

f

z

(mm)

a

p

(mm)

0,1-0,5

0,2-3

-

0,1-0,5

0,2-3

-

-

-

Material

steel

stainless steel

cast iron

non-ferrous

materials

high-temperature

alloys

hardened steel

Quality

Coating

Application

K10 polished

roughing

pre finishing

finishing

-

-

-

100

450

800

100

450

800

100

450

800

-

-

P40 PVTi

roughing

pre finishing

finishing

100

160

220

100

175

250

140

200

260

-

100

130

160

100

130

160

-

-

-

-

Feed per tooth (fz) | d.o.c. (ap)

Cutting speed (Vc in m/min)

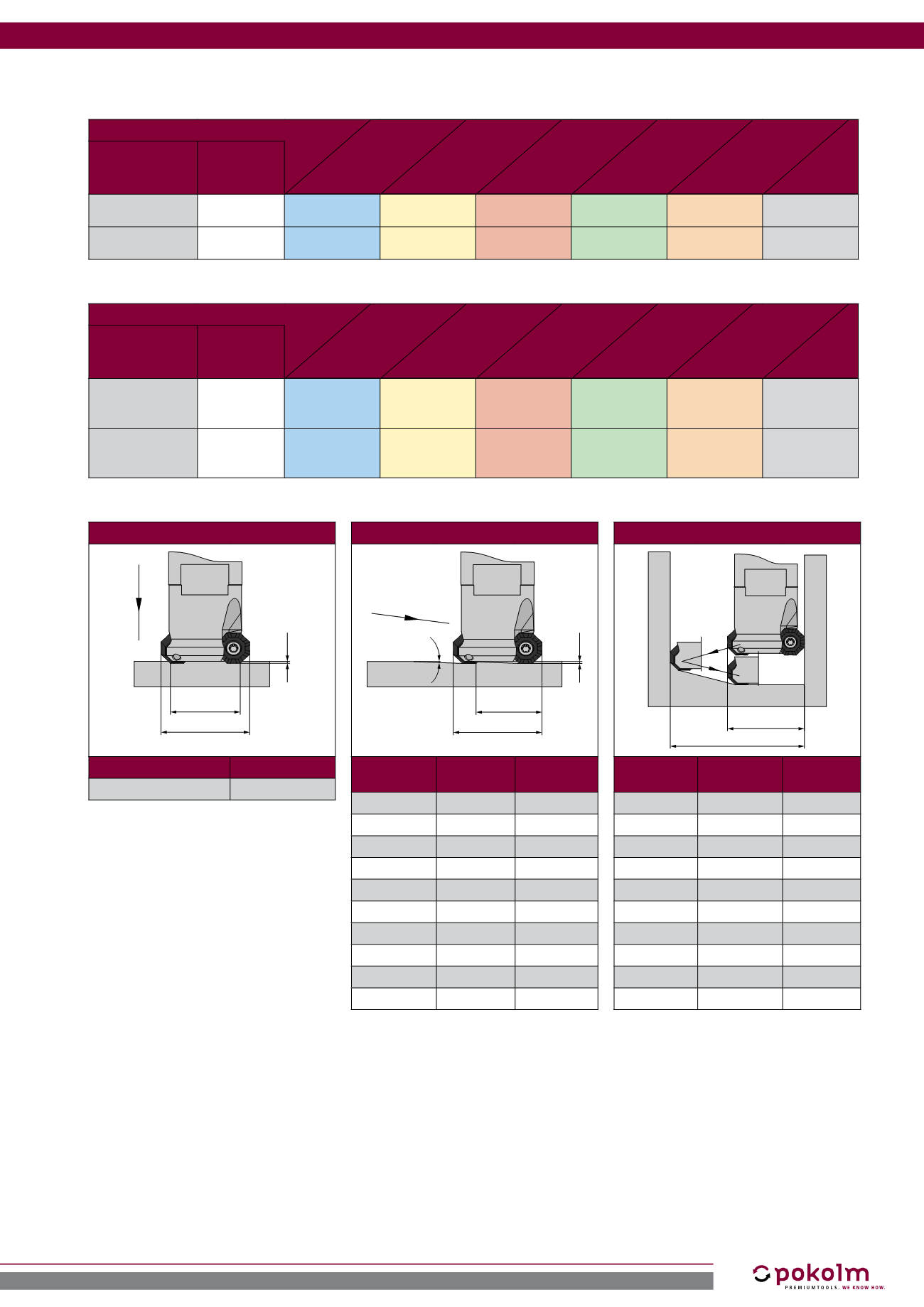

Extended operation data

Ramping

α

Y

d

1

X

Cutter diam.

d1

α

°

y

35

<16

11.6

40

<11

16.6

42

<10

18.6

50

<7

26.6

52

<6,5

28.6

63

<4,5

39.6

66

<4

42.6

80

<3

56.6

100

<2

76.6

125

<1,5

101.6

Helix

D min max

d

1

Cutter diam.

d1

D

min

D

max

35

46.6

70

40

56.6

80

42

60.6

84

50

76.6

100

52

80.6

104

63

102.6

126

66

108.6

132

80

136.6

160

100

176.6

200

125

226.6

250

Plunging

d

1

d

p

X

Cutter diam. d1

X

max

35-125

3.5