FROM PRACTICE TO PRACTICE

O

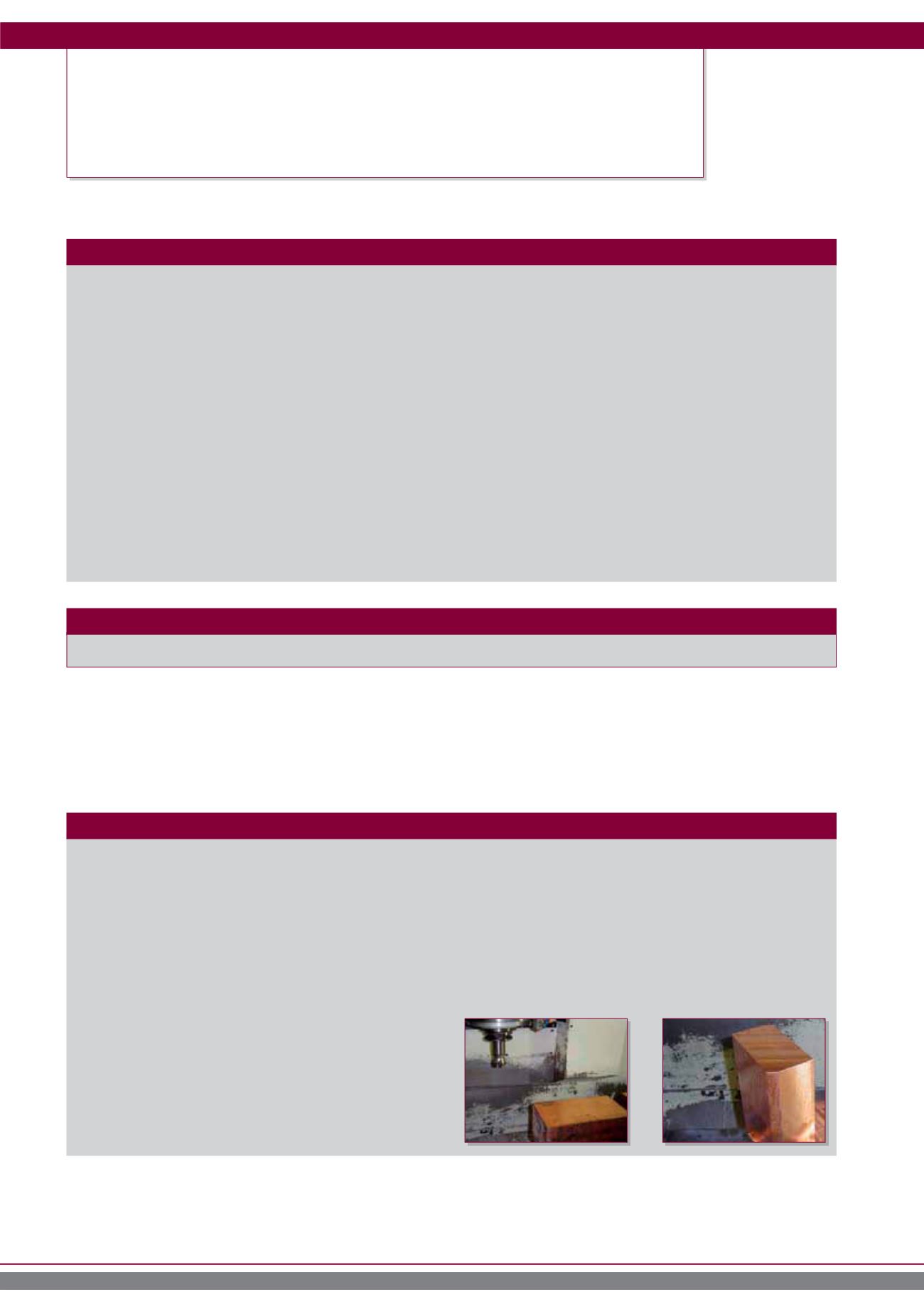

Optimizing of machining a component from Cu-HCP

(CW021A) (best selected copper min.99.5% purity),

with a tensile strength of approx. 300 N/mm² only, but

a breaking elongation of over 40%. The metal removal

volume for this component was 55%, for a quantity of 48

pieces. Previously, this component with unmachined dimen-

sions of 258mm long, 123mm wide and 211mm high was

machined with a Square Shoulder Face- and Slot Milling

Cutter with inserts having 0.8mm corner radius. But with

this tool, maximum cutting depth of a

p

= 3mm could be

realized, otherwise the component started vibrating under

the enormous cutting pressure. This was a very negative in-

fluence to the roughing operation. Although the customer

had rated the tool life of the inserts as satisfying, this was

not our valuation at all.

The no. of components was increasing constantly , and re-

garding production capacity, a decision had to be made. A

solution for better machining possibilities was found by our

applications engineers immediately. The new milling cutter

body from our

Slotworx

®

-L range 5 52 368

(52mm diam., r = 1) should be suitable outstandingly for

this application, and it was selected together with our new

indexable inserts 05 68 896, specially developed for cutting

corrosion- acid- and heat-resistant materials, having sharp,

but slightly radiused cutting edges and our special coating

with lubrication additives. This special coating avoids chip-

built-up of this best selected copper and cares together with

a sufficient coolant supply for optimum chip removal.

T

his component has been produced countour-parallel in

z-constant cycle in climb milling as well as conventional

milling. Regarding machining time, the feed rate and thus

the chip volume has been increased by 4 times. This results

in a reduction of the previous machining time from approx.

30 minutes to slightly more than 6 minutes. Through the spe-

cial design of the minor cutting edge of these

Slotworx

®

-L

inserts we could achieve very good surface smoothness and

minor waviness in the vertical parts of the component, even

in cutting depth a

p

of 5mm.

component

:

Nut

material

:

Cu-HCP, CW021A

arbor

:

50 22 710 (∅22, SK 50)

cutter body

:

5 52 368 (∅52 / R 1)

insert

:

05 68 896, M40

coating

:

PVST

overhang

:

103mm

v

c

(speed.):

571 m/min

v

f

(feed rate):

4,000mm/min

S

(revolutions):

3,500 1/min

f

z

(feed per tooth):

0.229mm

a

p

(depth of cut):

5mm

a

e

(width of cut):

32mm

chip volume

:

640 cm

3

/min

machining time

:

06:07 min

Machining time of this component has been reduced from 5

to 1.5 hours. This results – for 48 components and a calcu-

lated machine hour rate of 50€/hour – in savings of approx.

more than 8000 €. Plus an increased machine availablility

of 168 hours, which represents working hours of a com-

plete month anyhow. This time saving can be used for other

projects.

Cu-HCP

MACHINE

MATERIAL

MACHINE CONTROL

OKUMA

Okuma CNC

job description:

EXAMPLE FROM PRACTICE:

RESULT:

22

slotworx

®

square shoulder face milling cutter bodies milling cutter bodies