15

major application

minor application

roughing

pre-finishing

finishing

Slotworx® - k15°

HF | Size M - diam. 16 - 52 mm

• exceptionally suitable for High Feed Machining of hardened materials

up to 60+2HRC.

• PVTiH Coating well suited for milling of die steels, f.e. 1.2714.

• extremely long life time and high running smoothness because of the adapted

cutting surface geometry.

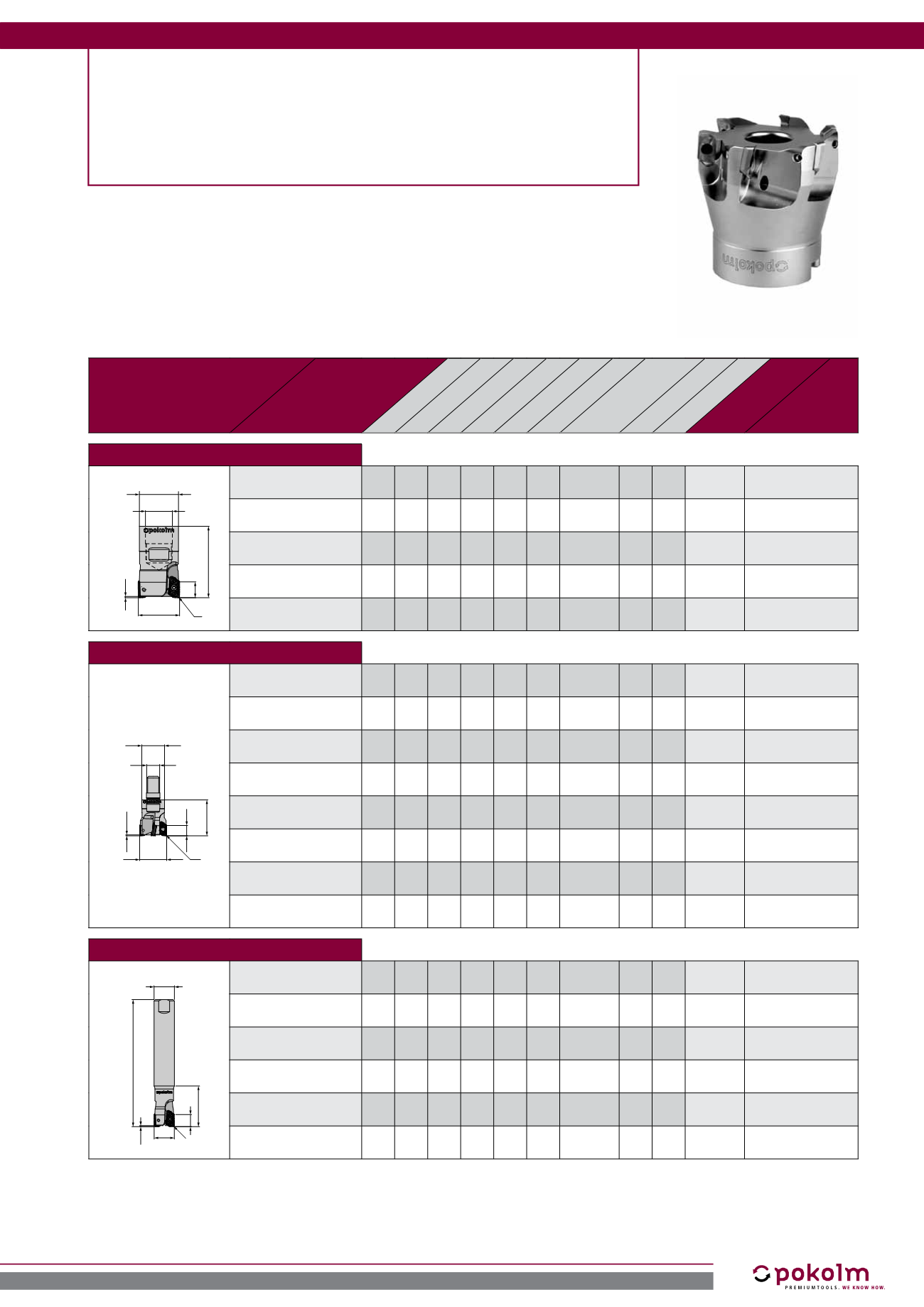

Milling cutter bodies

Catalogue no.

Accessories

Features

d

1

l

r

l

3

l

2

l

1

d

2

d

3

z

DuoPlug®

l

2

l

3

l

d

1

d

3

r

d

2

2 16 267 SG 16 10 1.4 38 2.5 -

M 10 15 2 A, C, D,

E, F

2 20 267 SG 20 10 1.4 40 2.5 -

M 12 18.6 2 A, C, D,

E, F

3 25 267 SG 25 10 1.4 43 2.5 -

M 16 23.5 3 A, C, D,

E, F

Threaded shank end mill bodies

l

d

3

d

2

l

2

l

3

d

1

r

2 16 267 16 10 1.4 29 2.5 -

M 8 13.8 2 A, C, D,

E, F

2 20 267 20 10 1.4 29 2.5 -

M 10 18 2 A, C, D,

E, F

3 20 267 20 10 1.4 29 2.5 -

M 10 18 3 A, C, D,

E, F

3 25 267 25 10 1.4 33 2.5 -

M 12 21 3 A, C, D,

E, F

4 25 267 25 10 1.4 33 2.5 -

M 12 21 4 A, C, D,

E, F

4 32 267 32 10 1.4 43 2.5 -

M 16 29 4 B, C, D,

E, F

5 32 267 32 10 1.4 43 2.5 -

M 16 29 5 B, C, D,

E, F

5 42 267 42 10 1.4 43 2.5 -

M 16 29 5 B, C, D,

E, F

Plain shank end mill bodies

d

1

l

3

l

l

2

l

1

d

2

r

2 32 16 167 G 16 10 1.4 32 2.5 165 diam. 16 -

2 A, C, D,

E, F

3 40 20 167 G 20 10 1.4 40 2.5 165 diam. 20 -

3 A, C, D,

E, F

3 50 25 167 G 25 10 1.4 50 2.5 225 diam. 25 -

3 A, C, D,

E, F

4 50 25 167 G 25 10 1.4 50 2.5 225 diam. 25 -

4 A, C, D,

E, F

slotworx

®

high feed rate cutters milling cutter bodies