14

internal coolant supply

DuoPlug

®

incorporated inserts

clamping flat

stock item, subject to confirmation

on request

available as long as stock lasts

latest items !

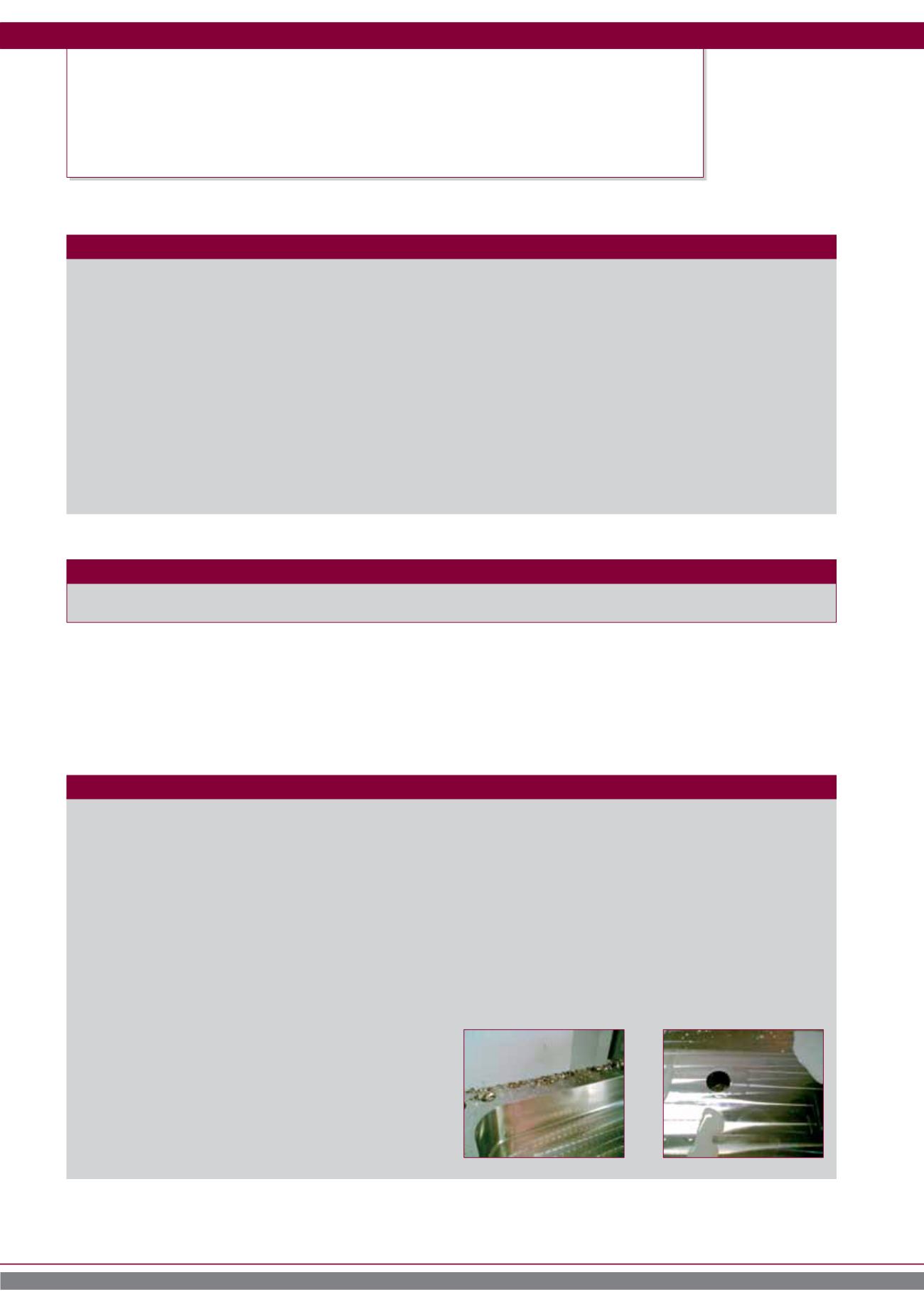

FROM PRACT ICE TO PRACT ICE

P

roducing absolutely accurate 90°-walls on holding blocks

of injection moulding dies for plastics processing has

always been a goal of the company Wonde from the town

of Heiligkreuz-Steinach. Only a perfectly prepared holding

block guarantees highest possible accuracy and durability

for following production processes of all injection moulding

dies. On this job, special attention was required for precis-

ion and economic efficiency regarding tool costs. Till now,

the customer was using a 25 mm diam. multiple flute solid

carbide end mill for this job. He was limited through given

dimensions for reach and overall length of this end mill.

For this particular and for many other applications, our new

Slotworx

®

-range is the ideal compliment, where a solid

carbide end mill reaches its limitation. This is a golden op-

portunity for our

Slotworx

®

-style of end mills. Our new

range, with precision-ground inserts, is ready to face these

challenges –and, it has passed its examination in masterly

manner and velocity.

T

his holding block, which had to be machined, had a re-

maining stock of 1 mm all over, after roughing. This part

had been programmed in a z-constant circular-pocket cycle

with constant depth setting increments in radial and axial

direction. We found a rigid set-up on that DMU 100P milling

machine, a high-speed and dynamic 5-axis machining centre

with vertical HSK-63A taper connection. All these conditions

are ideal qualifications for using Pokolm-

Slotworx

®

-

milling cutters.

Expected and requested accuracy has been reached im-

mediately to customer’s satisfaction. Now, the customer is

able to produce his holding blocks with those exceptionally

required tool-overhangs of > 100 mm process-reliable and

efficient in very short time. This kind of tooling is also avai-

ble now for machining aluminium, and it is the right way

for further success of Pokolm-tooling.

component:

holding block

material:

1.2312

arbor:

60 25 A63 S

(25 mm diam., HSK 63)

extension:

75 16 603

cutter body:

3 25 267 SG

(25 mm diam., r = 1)

insert:

04 67 844, P40

coating:

PVGO

overhang:

178 mm

vc (speed):

314 m/min

vf (feed rate):

2.000 mm/min

S (revolutions):

4.000 1/min

fz (feed per tooth):

0,25 mm

ap (depth of cut):

3,0 mm

ae (width of cut):

0,1 mm

MACHINE

EXAMPLE FROM PRACTICE:

Deckel Maho DMU 100 P

MATERIAL

RESULT:

1.2312

PROGRAMMING SYSTEM

Euklid

job description:

Object 184265

slo worx

®

square shoulder face milling cutter bodies milling cutter bodies