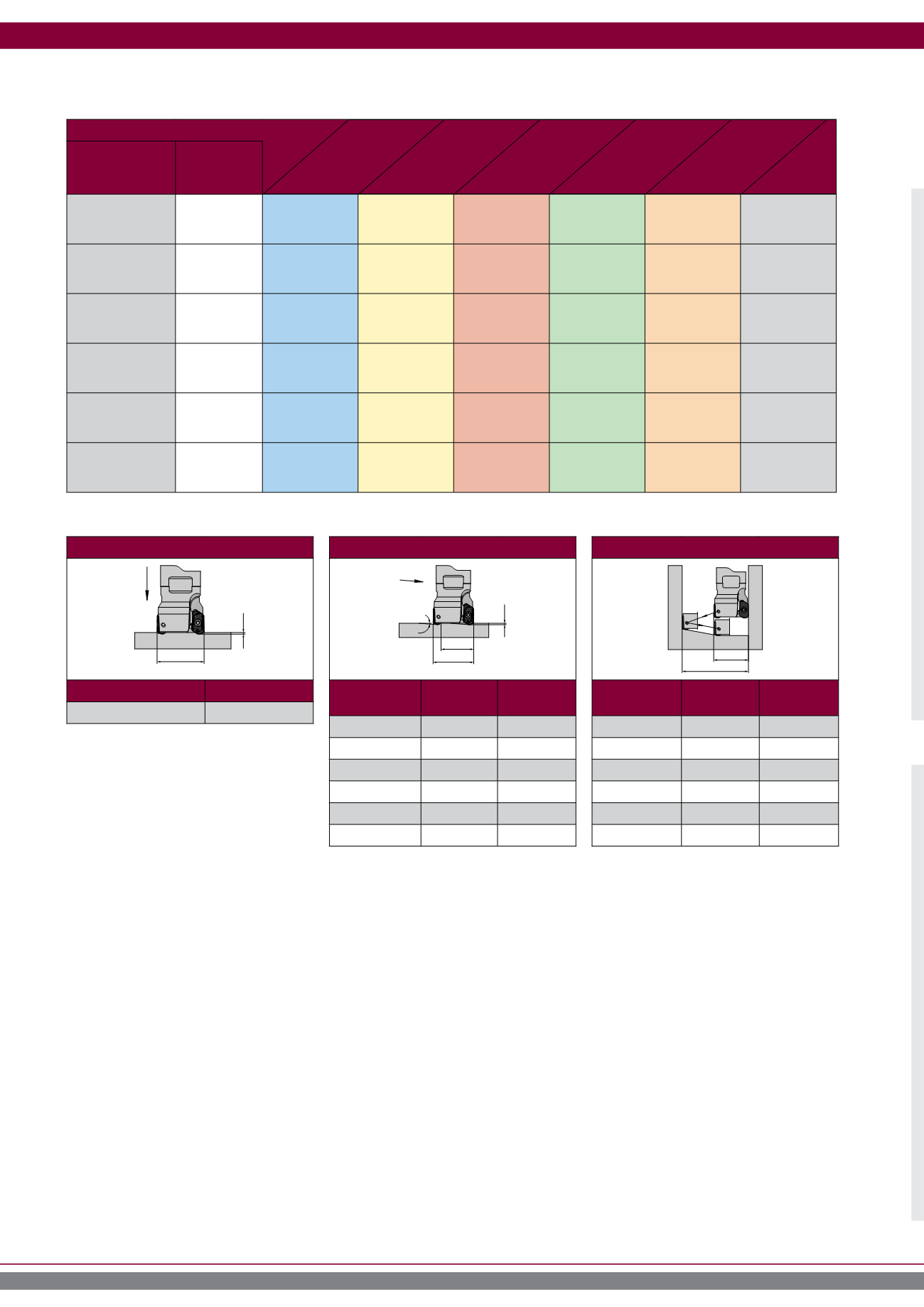

Plunging

d

1

X

Cutter diam. d1

X

max

16-52

0.85

Ramping

d

1

Y

X

α

Cutter diam.

d1

α

°

y

16

4

12

20

3

16

25

2,5

21

32

1,7

28

42

1,2

38

52

1

41.3

Helix

D min max

d

1

Cutter diam.

d1

D

min

D

max

16

26

32

20

34

40

25

44

50

32

58

64

42

78

84

52

98

104

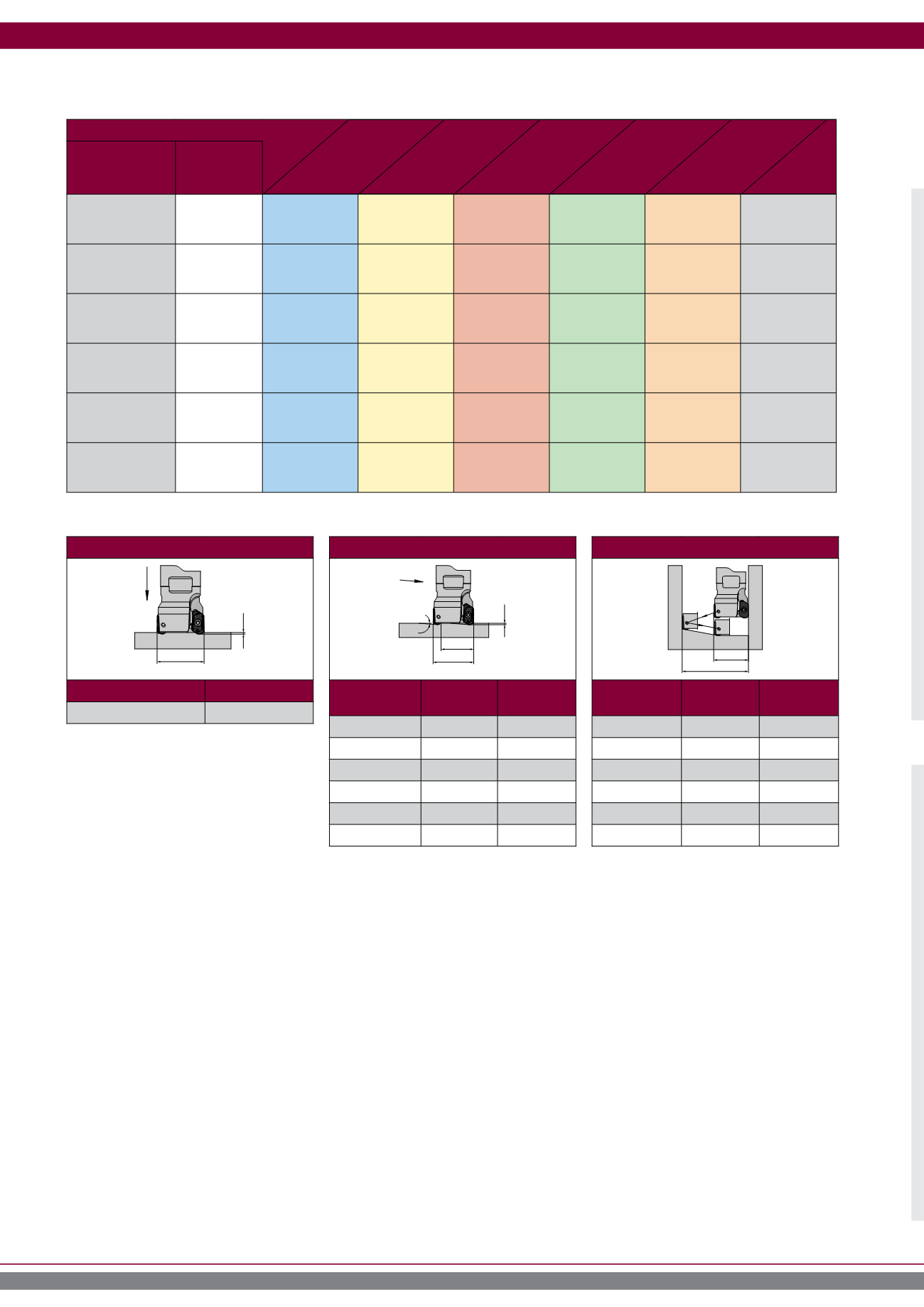

Material

steel

stainless steel

cast iron

non-ferrous

materials

high-temperature

alloys

hardened steel

Quality

Coating

Application

HSC 05 PVTi

roughing

pre finishing

finishing

120

185

250

150

275

400

-

-

100

150

200

150

225

300

-

-

-

35

143

250

35

143

250

-

HSC 05 PVTiH

roughing

pre finishing

finishing

120

185

250

150

275

400

-

-

100

150

200

150

225

300

-

-

-

35

143

250

35

143

250

-

P40 PVGO

roughing

pre finishing

finishing

100

150

200

100

150

200

-

-

-

-

-

-

K10 PVGP

roughing

pre finishing

finishing

-

-

150

185

220

160

190

220

-

-

-

80

115

150

100

150

200

-

M40 PVST

roughing

pre finishing

finishing

80

140

200

100

150

200

-

80

130

180

100

155

210

-

-

-

30

55

80

40

65

90

-

-

M35 PCTC

roughing

pre finishing

finishing

-

110

155

200

120

175

230

-

-

-

30

65

100

40

75

110

-

-

Extended operation data

Cutting speed (Vc in m/min)

Slotworx® - k15° High feed rate cutters (HSC)

190