* corner radius to be programmed

TRIGAWORX®

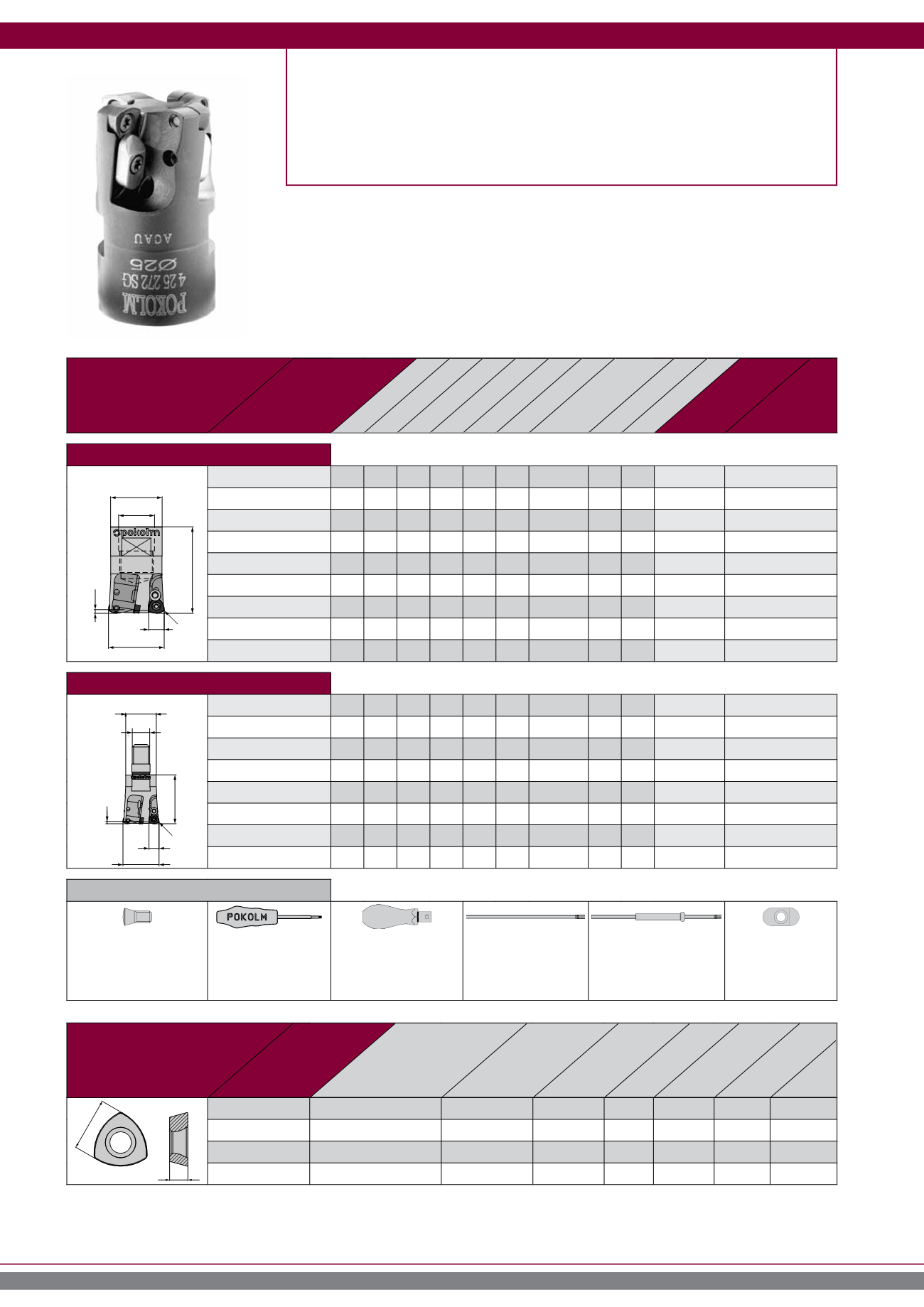

Size S

Indexable inserts

Catalogue no.

DIN Specification

Carbide Grade

Coating

l

s

r

M

l

s

02 72 835 WDHX 070205 SN

HSC 05

PVTi

7

2.38

0.5

M 2.5

02 72 840 WDHX 070205 SN

P40

PVTi

7

2.38

0.5

M 2.5

Milling cutter bodies

Catalogue no.

Accessories

Features

d

1

l

r

p

* l

3

l

2

l

1

d

2

d

3

z

DuoPlug®

l

2

l

d

1

l

3

d

3

d

2

r

p

2 16 272 SG 16 7 1.5* 38.5 1 -

M 10 15 2 A, B, C, D, E, F

Threaded shank end mill bodies

r

p

l

2

d

1

l

l

3

d

3

d

2

2 16 272 16 7 1.5* 28.5 1 -

M 8 13.8 2 A, B, C, D, E, F

3 20 272 20 7 1.5* 28.5 1 -

M 10 18 3 A, B, C, D, E, F

4 25 272 25 7 1.5* 32.5 1 -

M 12 21 4 A, B, C, D, E, F

Accessories

25 500

Torx screw

A > Page

07 500

Torx-screwdriver

B > Page

TV 04-1

Screwdriver torque

Vario®-S with window

scale, C > Page

T7 500

Torx interchangeable bit

for Torque Vario®

D > Page

T7 502

Torx MagicSpring compati-

ble bit f. Torque Vario®

E > Page

12 510

clamping claw for

Trigaworx® S

F > Page

• allows extremely high feed rates per tooth up to fz = 1.5 mm

• better utilization of insert because of its 3 effective cutting edges

• very smooth operation, especially in deep slots or profiles

Especially for roughing operations

Trigaworx® High feed rate cutters (HSC)

180