34

latest items!

available as long as stock lasts

on request

stock item, subject to confirmation

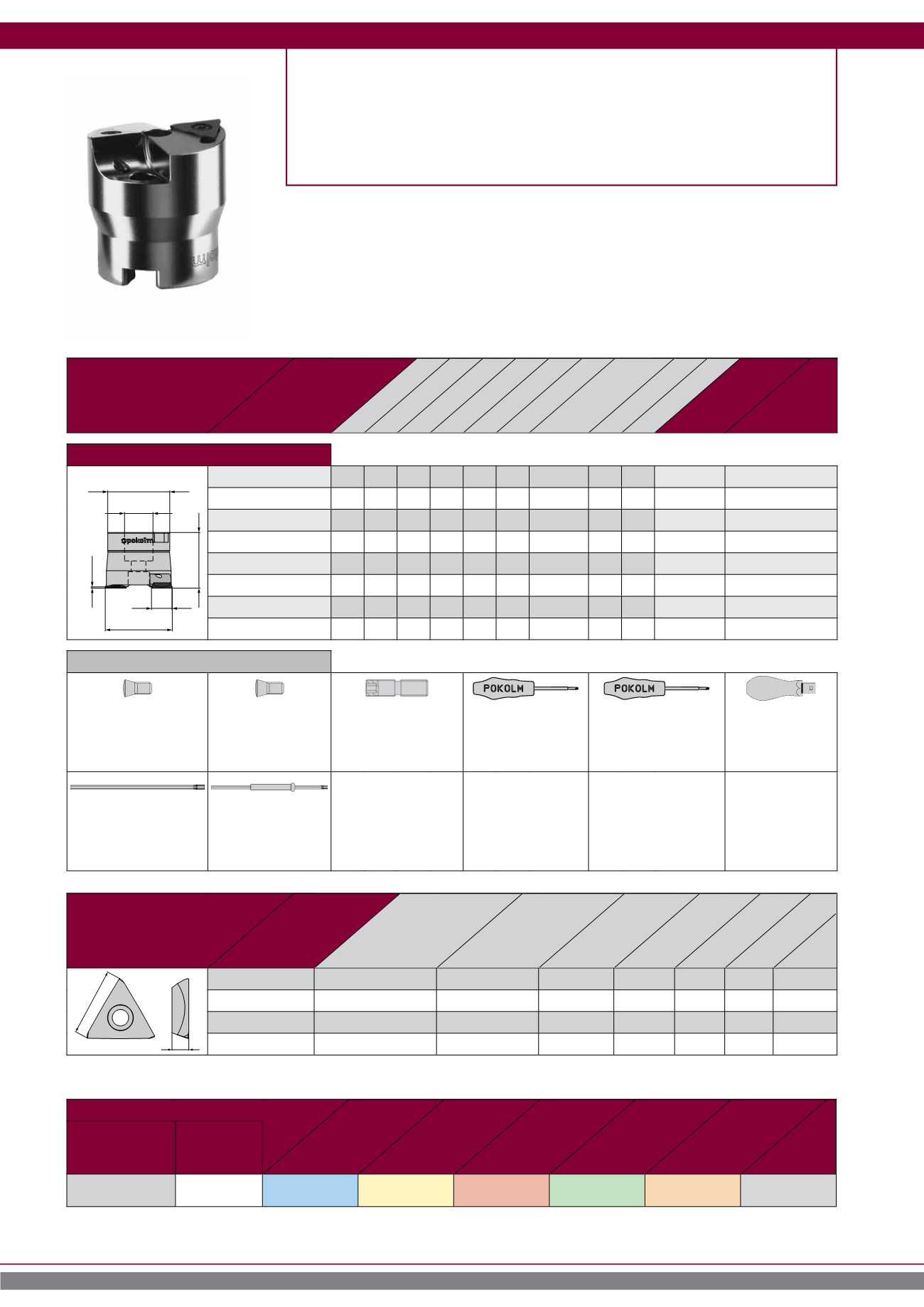

Material

steel

stainless steel

cast iron

non-ferrous

materials

high-temperature

alloys

hardened steel

Quality

Coating

Feed per

tooth | d.o.c.

HSC 05 PVTi

f

z

(mm)

a

p

(mm)

0,5-2

0,05-0,2

0,5-1

0,05-0,1

0,5-2

0,05-0,2

0,5-2

0,05-0,25

0,2-1

0,05-0,1

0,2-1

0,05-0,1

MIRROWORX®

Size M - diam. 42 - 100 mm

Indexable inserts

Catalogue no.

DIN Specification

Carbide Grade

Coating

l

s

r

M

s

l

04 84 835

TEHX 16T3 ZF

HSC 05

PVTi

14.32

4

-

M 3.5

Milling cutter bodies

Catalogue no.

Accessories

Features

d

1

l

r

l

3

l

2

l

1

d

2

d

3

z

Shell-type milling cutter bodies

d

3

l

2

l

l

3

d

1

d

2

2 42 384 42 14.32

43 1 -

diam. 16 35 2 A,B,C,D,E,F,G,H

2 52 384 52 14.32

43 1 -

diam. 22 48 2 A,B,D,E,F,G,H

2 66 384 66 14.32

53 1 -

diam. 27 60 2 A,B,D,E,F,G,H

2 80 384 80 14.32

53 1 -

diam. 27 60 2 A,B,D,E,F,G,H

2 100 384 100 14.32

53 1 -

diam. 32 70 2 A,B,D,E,F,G,H

Accessories

35 500 L

Torx screw

A > Page

45 500 L

Torx screw

B > Page

GWSTPS8ISK

hexagon socket set screw

C > Page

15 500

Torx-screwdriver

D > Page

20 500

Torx-screwdriver

E > Page

TV 2-8, Screwdriver

torque Vario®-S with

window scale. F >

Page

T15 500

Torx interchangeable bit for

Torque Vario®

G > Page

T15 502

Torx MagicSpring

compatible bit f. Torque

Vario®, H > Page

Milling instead of grinding is our slogan for these finishing milling cutters. Developed

for producing smooth and levelled surfaces with enormous feed rates.

These tools enter into grinding domains.

Feed per tooth (fz) | d.o.c. (ap)

Mirroworx® Face milling cutters