156

latest items!

available as long as stock lasts

on request

stock item, subject to confirmation

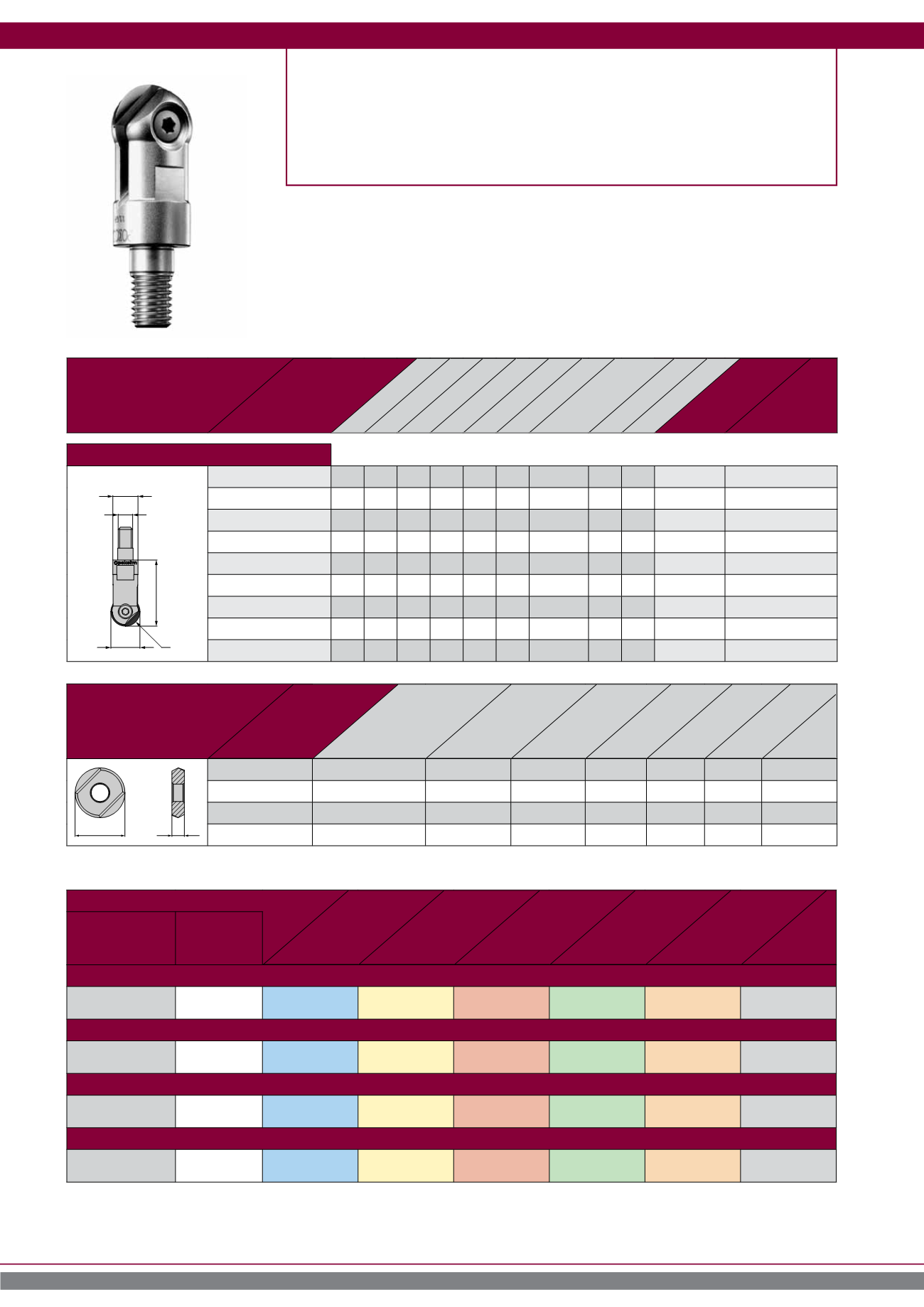

Material

steel

stainless steel

cast iron

non-ferrous

materials

high-temperature

alloys

hardened steel

Quality

Coating

Feed per

tooth | d.o.c.

d=10 mm

K05 PVTi

f

z

(mm)

a

p

(mm)

0,1

0,1

0,1

0,1

0,1

0,1

0,1

0,1

0,1

0,1

0,1

0,1

d=12 mm

K05 PVTi

f

z

(mm)

a

p

(mm)

0,12

0,1

0,12

0,1

0,12

0,1

0,12

0,1

0,12

0,1

0,12

0,1

d=16 mm

K05 PVTi

f

z

(mm)

a

p

(mm)

0,16

0,1

0,16

0,1

0,16

0,1

0,16

0,1

0,16

0,1

0,16

0,1

d=20 mm

K05 PVTi

f

z

(mm)

a

p

(mm)

0,2

0,1

0,2

0,1

0,2

0,1

0,2

0,1

0,2

0,1

0,2

0,1

CUTTERS FOR INSERTS WITH

4 CUTTING EDGES

diam. 10 mm - 20 mm

Indexable inserts

Catalogue no.

DIN Specification

Carbide Grade

Coating

d

s

r

M

d

s

10 10 860

ROHX 1002

K05

PVTi

10

2.5

5

M 3.5

10 12 860

ROHX 1203

K05

PVTi

12

3

6

M 4.0

10 16 860

ROHX 16T3

K05

PVTi

16

4

8

M 5.0

10 20 860

ROHX 2004

K05

PVTi

20

5

10

M 5.0

Milling cutter bodies

Catalogue no.

Accessories

Features

d

1

d r

l

3

l

2

l

1

d

2

d

3

z

Threaded shank end mill bodies

r

d

l

3

d

3

d

2

10 210 M6 10 10 5 28.5 -

-

M 6 9.75 2 A, B, C, D, E

12 210 M6 12 12 6 28.7 -

-

M 6 11.5 2 A, B, C, D, E

16 210 16 16 8 36.4 -

-

M 8 13.8 2 A, B, C, D, E

20 210 20 20 10 36.9 -

-

M 10 18 2 A, B, C, D, E

The special insert geometry of these tools makes it ideally suited for finishing and pre-

finishing operations on modern high-speed milling machines with 5 axes.

The advantage of the insert with 4 cutting edges is: it is reversible, thus it doubles its

productivity.

Optimum cutting conditions can only be achieved with an approach angle of

spindle.

Feed per tooth (fz) | d.o.c. (ap)

Cutters for inserts with 4 cutting edges Ball end bull end mill cutters