68

latest items!

available as long as stock lasts

on request

stock item, subject to confirmation

SPINWORX®

r6 - diam. 32 - 66 mm, 7° positive rake angle

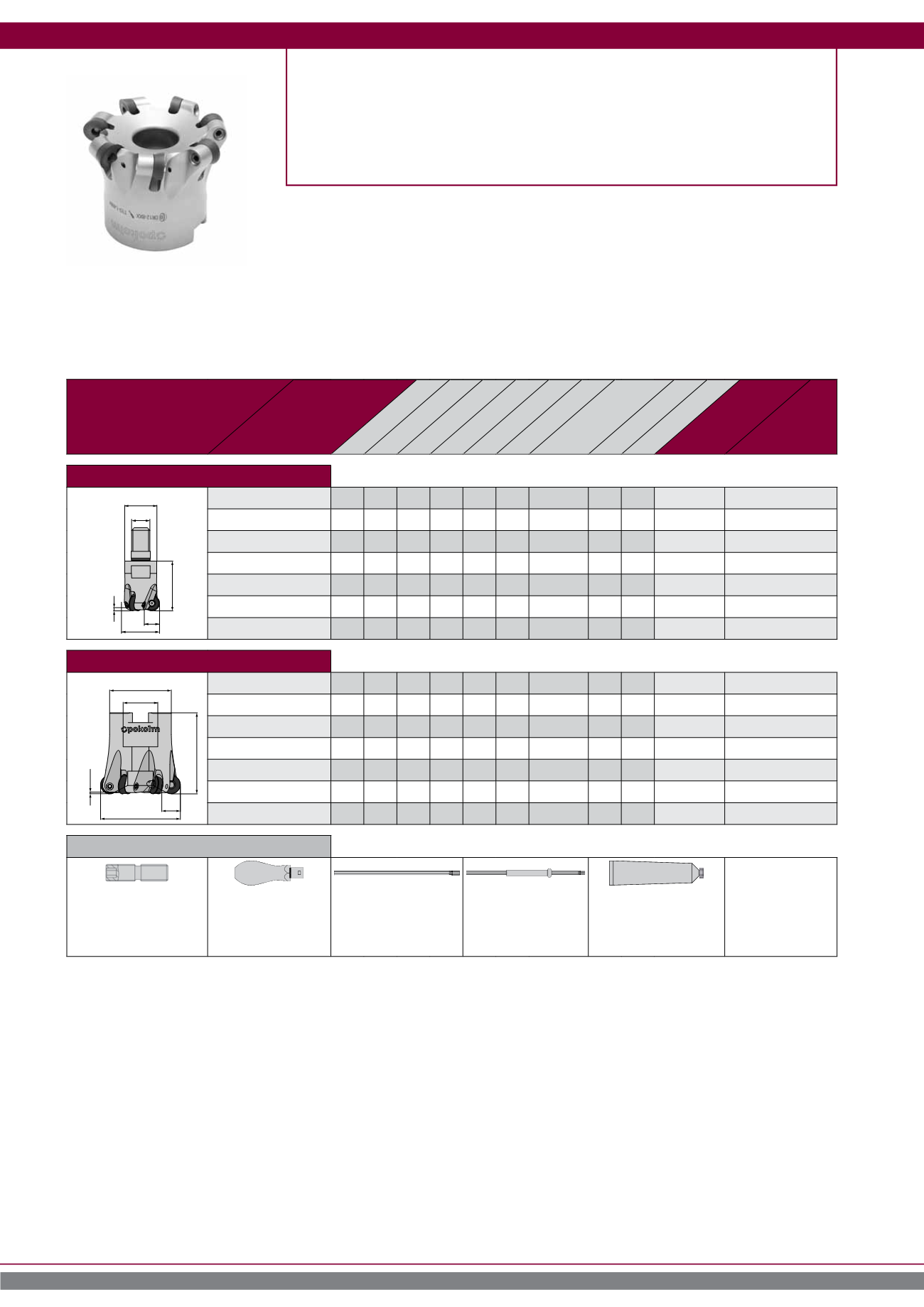

Milling cutter bodies

Catalogue no.

Accessories

Features

d

1

d r

l

3

l

2

l

1

d

2

d

3

z

Threaded shank end mill bodies

d

2

d

d

1

d

3

l

2

l

3

DR12-032-E16-04 32 12 6 42.5 2.8 -

M 16 29 4 B, C, D, E

DR12-035-E16-03 35 12 6 42.5 2.8 -

M 16 29 3 B, C, D, E

DR12-035-E16-04 35 12 6 42.5 2.8 -

M 16 29 4 B, C, D, E

DR12-035-E16-05 35 12 6 42.5 2.8 -

M 16 29 5 B, C, D, E

Shell-type milling cutter bodies

l

3

d

3

l

2

d

1

d

d

2

DR12-040-A16-05 40 12 6 42.5 2.8 -

diam. 16 35 5 A, B, C, D, E

DR12-042-A16-05 42 12 6 42.5 2.8 -

diam. 16 35 5 A, B, C, D, E

DR12-050-A22-06 50 12 6 52.5 2.8 -

diam. 22 40 6 B, C, D, E

DR12-052-A22-06 52 12 6 52.5 2.8 -

diam. 22 40 6 B, C, D, E

DR12-063-A27-06 63 12 6 52.5 2.8 -

diam. 27 48 6 B, C, D, E

DR12-066-A27-07 66 12 6 52.5 2.8 -

diam. 27 48 7 B, C, D, E

Accessories

GWSTPS8ISK

hexagon socket set screw

A > Page

T10-1,4NM

Torque Fix® - S torque

screwdriver

B > Page

T10 500

Torx interchangeable bit

for Torque Vario®

C > Page

T10 502

Torx MagicSpring

compatible bit f. Torque

Vario®, D > Page

Z 00043

HTC ceramic paste WS

600 005

E > Page

Highly efficient SPINWORX systems also available in intermediate sizes.

• wide range of use for almost all areas of application

• effective use of the cutting edge

• with specially adapted primary and secondary coolant supply.

• unrivalled in terms of machining volume and tool life.

CAUTION! PLEASE NOTE!

For optimum results with the SPINWORX®-tooling system we recommend using internal

coolant supply air, emulsion or MQL for chip removal in the tool! Wet machining up to

max speed Vc of 140 m/min!

SPINWORX® Copy cutters