uu

QUADWORX

®

M

in

1.2312 /

40CrMnMoS8-6

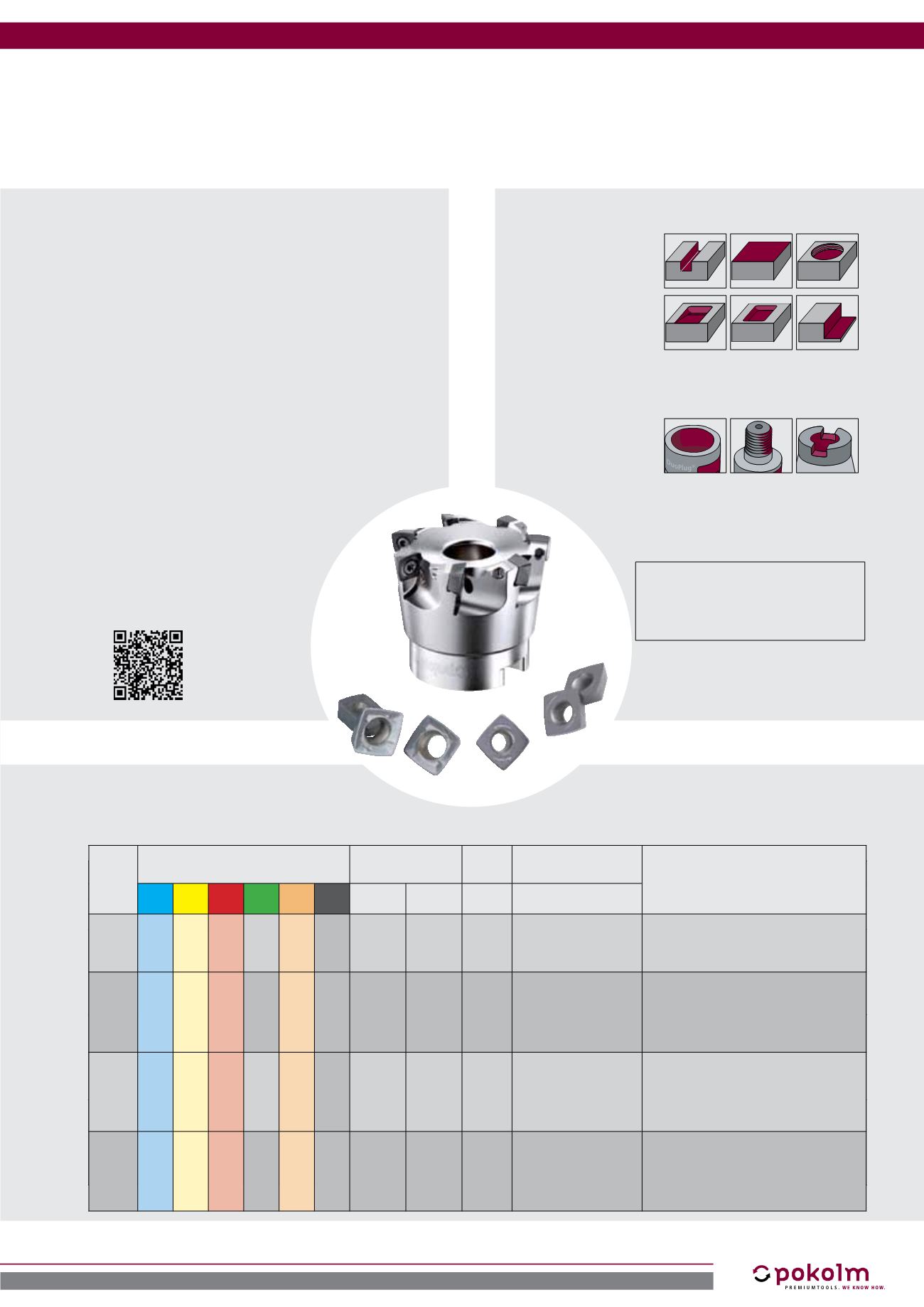

P M

K

N S

H

S

-

0,2 - 1,5 0,2 - 0,5 7,0

1,3

P40 PVTi

M40 PVST

HSC05 PVTi

M

-

0,3 - 2,0 0,2 - 1,2 9,0

1,5

P25 PVTi

P40 PVTi

P40 PVGO

M40 PVST

K10 PVTi

L

-

0,3 - 2,5 0,25 - 1,5 10,0

2,3

P25 PVTi

P40 PVTi

P40 PVGO

M40 PVST

K10 PVTi

P M

K

N S

H

S

-

0.2 - 1.5 0.2 - 0.5 7.0

1.3

P40 PVTi

M40 PVST

HSC 5 PVTi

M

-

0.3 - 2.0 0.2 - 1.2 9.0

1.5

P25 PVTi

P40 PVTi

P40 PVGO

M40 PVST

K10 PVTi

L

-

0.3 - 2.5 0.25 - 1.5 10.0

2.3

P25 PVTi

P40 PVTi

P40 PVGO

M40 PVST

K10 PVTi

XL

-

-

0.3 - 2.0 0.2 - 2.2 13

3.3

P25 PVTi

P25 PVGO

P40 PVGO

M40 PVST

K10 PVTi

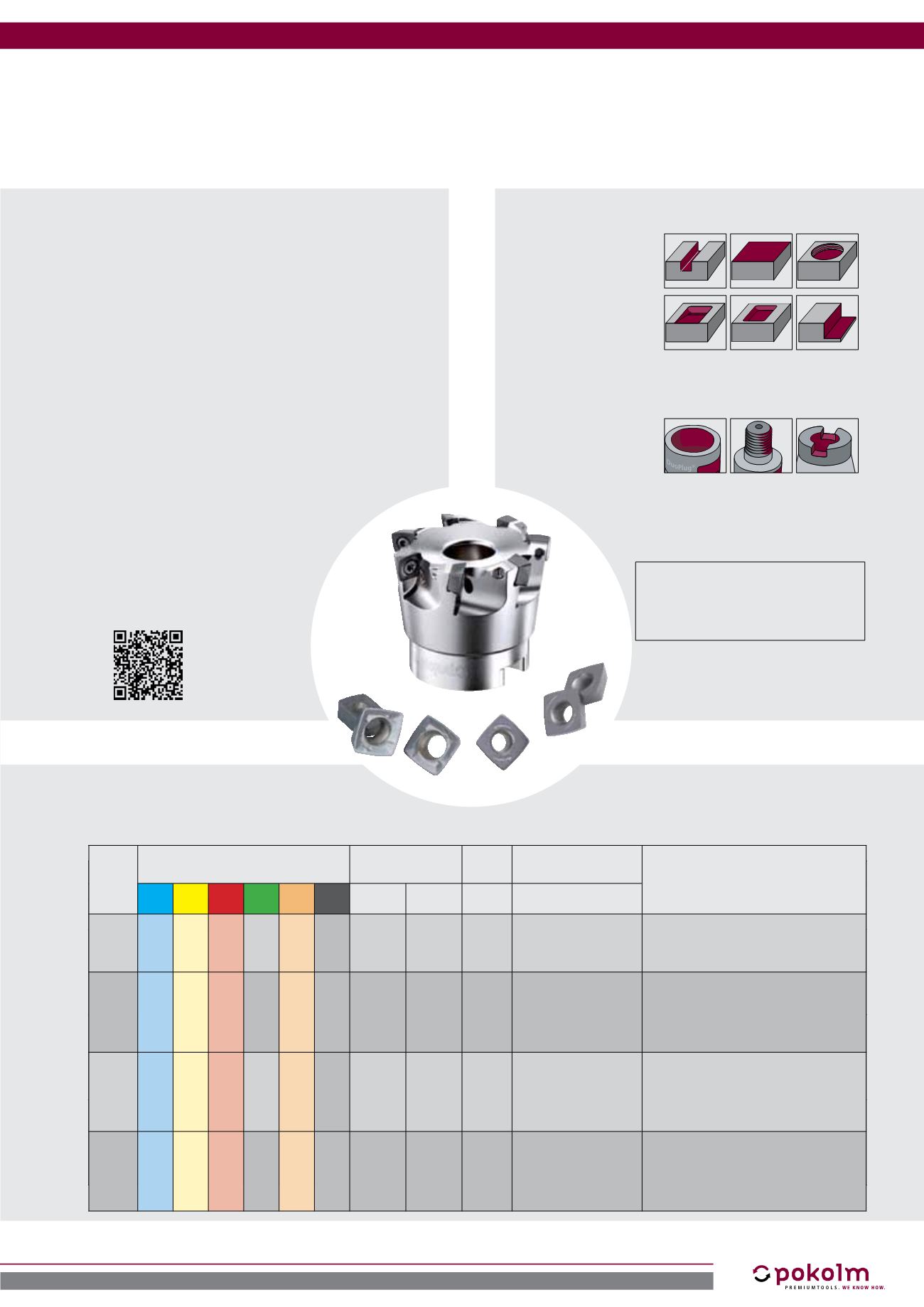

Machining types

Connection types

Properties

Cutting materials

Sizes

Page

Practical video

uu

Universal use in high-feed rate cutters

uu

Very high removal rates and extremely soft cutting

for more machine capacity

uu

4 cutting edges / insert for highly economical use

uu

Twisting is eliminated by positioning of the inserts

via a second flank and 90° positioning

uu

Maximum process reliability with interrupted

cutting due to secure positioning of the inserts

uu

With wiper edge and large radius very high surface

qualities are achieved in the rough machining stage

S: diam. 14 - 25 mm 168

M: diam. 22 - 52 mm 170

L: diam. 35 - 80 mm 173

XL: diam. 32 - 100 mm 176

QUADWORX

®

HIGH FEED RATE CUTTERS

Feed rate squared - maximum economic ef ficiency for universal use

Size

ISO standard

feed per tooth | d.o.c.

a

p

(mm)

f

z

(mm)

length

l (mm)

corner radius

to be programmed

r

p

(mm)

Carbide grade | coating

167