* corner radius to be programmed

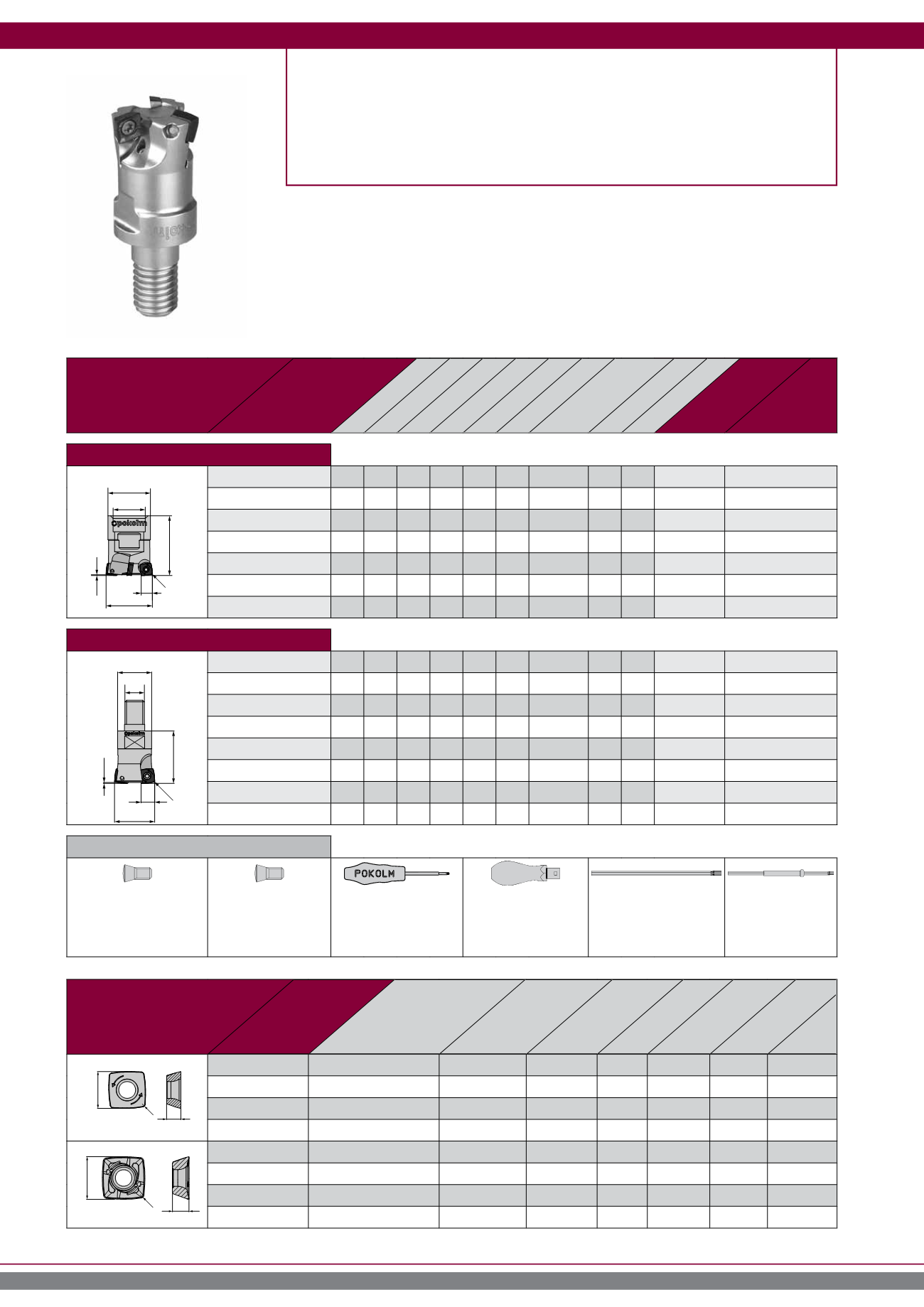

QUADWORX®

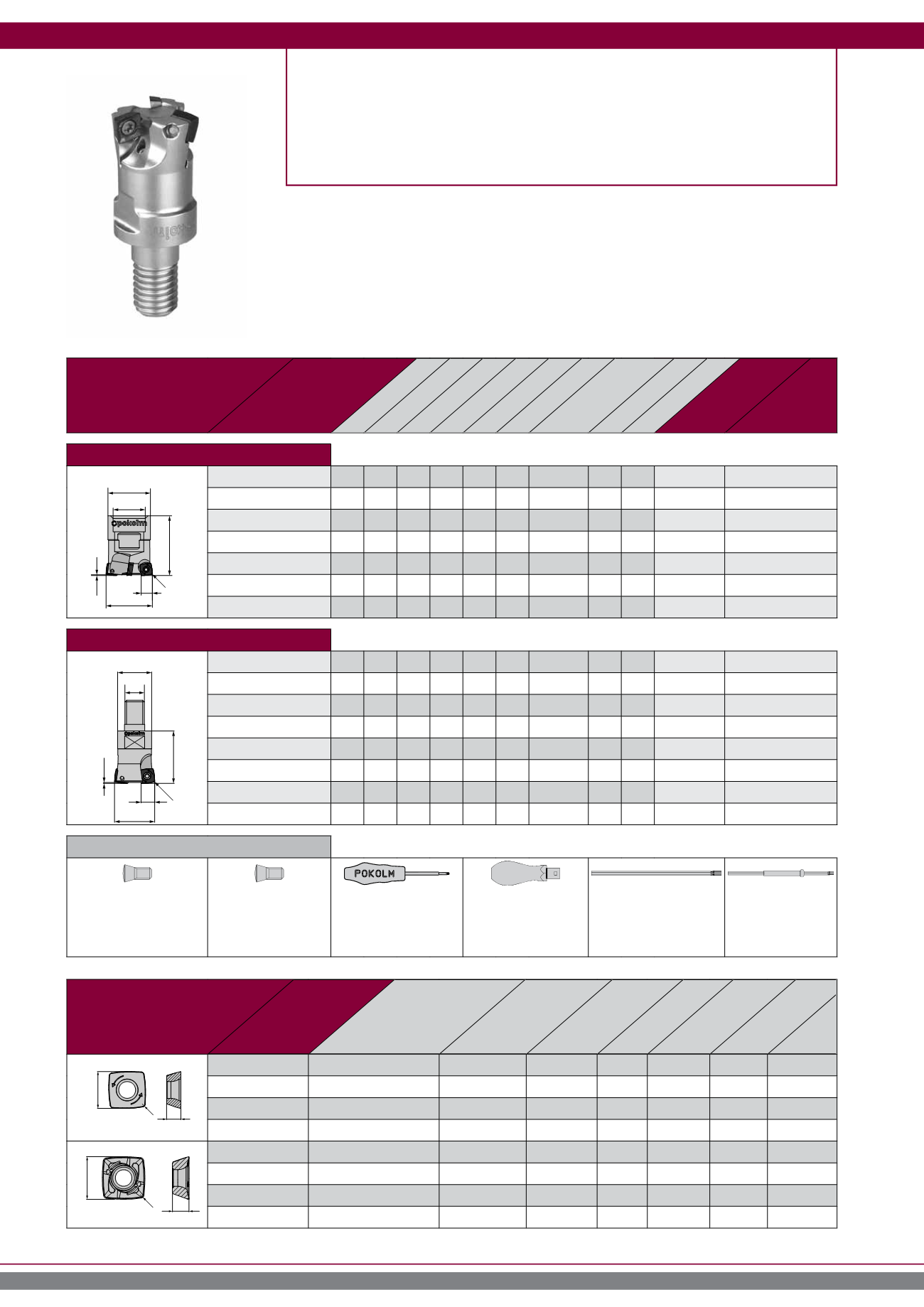

Size S

Indexable inserts

Catalogue no.

DIN Specification

Carbide Grade

Coating

l

s

r

M

s

l

r

02 47 837 SDMX 070205 SN

HSC 05

PVTi

7

2.38

0.5

M 2.5

02 47 842 SDMX 070205 SN

P40

PVTi

7

2.38

0.5

M 2.5

l

r

s

02 47 896 SDMT 070205 SN

M40

PVST

7

2.38

0.5

M 2.5

Milling cutter bodies

Catalogue no.

Accessories

Features

d

1

l

r

p

* l

3

l

2

l

1

d

2

d

3

z

DuoPlug®

l

1

d

3

d

1

l

3

d

2

l

r

p

2 16 247 SG 16 7 1.3* 31 1 -

M 10 15 2 B, C, D, E, F

3 18 247 SG 18 7 1.3* 31 1 -

M 10 15 3 A, C, D, E, F

3 20 247 SG 20 7 1.3* 33 1 -

M 12 18.6 3 A, C, D, E, F

4 25 247 SG 25 7 1.3* 35 1 -

M 16 23.5 4 A, C, D, E, F

Threaded shank end mill bodies

l

2

l

3

d

3

d

2

r

p

l

d

1

2 14 247 14 7 1.3* 28.5 1 -

M 8 13.8 2 B, C, D, E, F

2 16 247 16 7 1.3* 28.5 1 -

M 8 13.8 2 B, C, D, E, F

3 18 247 18 7 1.3* 28.5 1 -

M 8 13.8 3 A, C, D, E, F

3 20 247 20 7 1.3* 28.5 1 -

M 10 18 3 A, C, D, E, F

4 25 247 25 7 1.3* 32.5 1 -

M 12 21 4 A, C, D, E, F

Accessories

25 500

Torx screw

A > Page

25 500 K

Torx screw

B > Page

07 500

Torx-screwdriver

C > Page

TV 04-1

Screwdriver torque

Vario®-S with window

scale, D > Page

T7 500

Torx interchangeable bit

for Torque Vario®

E > Page

T7 502, Torx Magic-

Spring compatible bit

f. Torque Vario®

F > Page

• four cutting edges per insert for extremely efficient operations

• very big metal removal rates and extremely easy cutting

• as a standard, every tool has our patent protected incorporated insert seats and

internal coolant supply

• allows extremely high feed rates per tooth up to fz = 1.5 mm

Quadworx® High feed rate cutters (HSC)

168