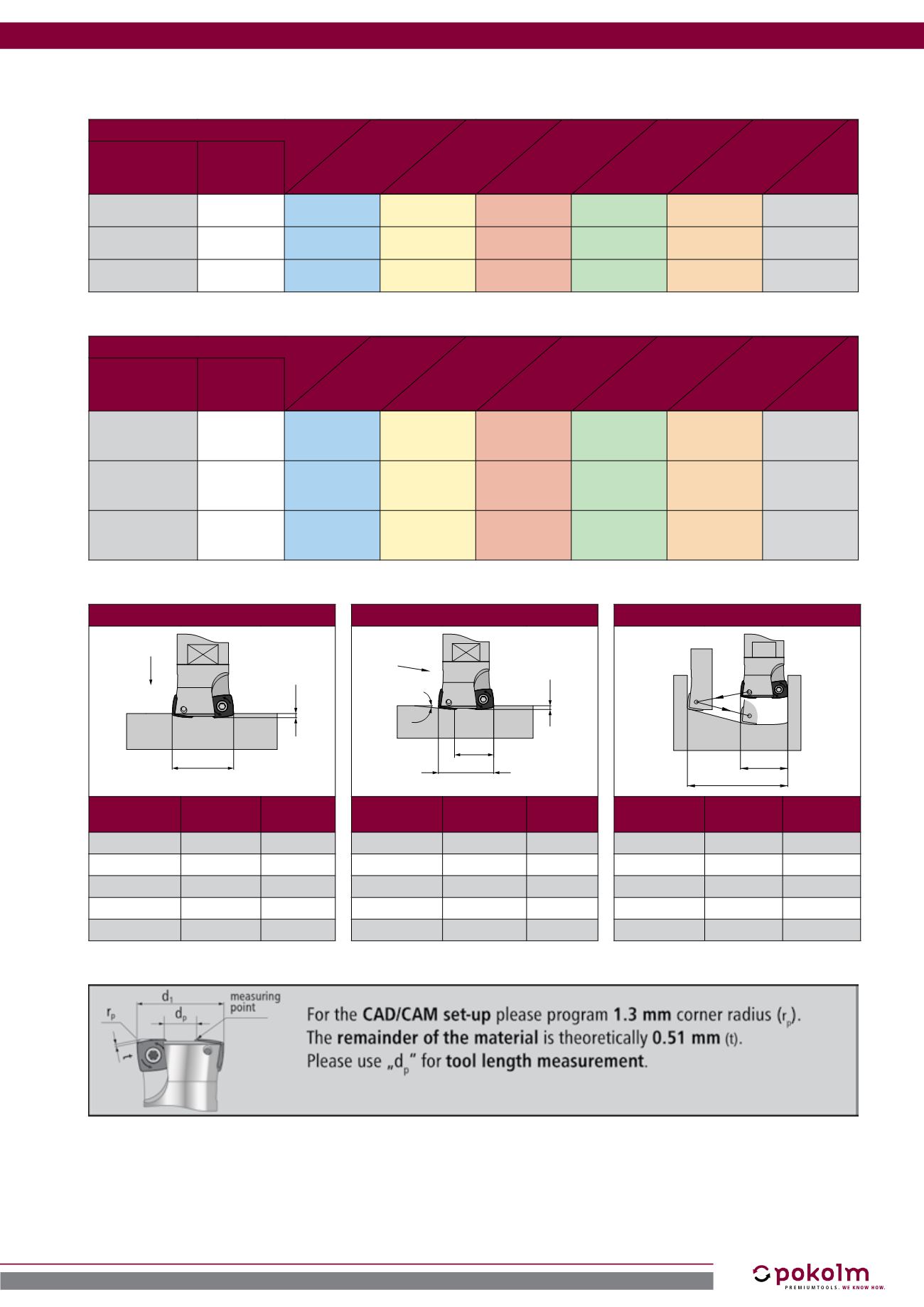

Technical information

Material

steel

stainless steel

cast iron

non-ferrous

materials

high-temperature

alloys

hardened steel

Quality

Coating

Feed per

tooth | d.o.c.

HSC 05 PVTi

f

z

(mm)

a

p

(mm)

-

-

0,2-1,5

0,2-0,5

-

-

0,1-1

0,1-0,5

P40 PVTi

f

z

(mm)

a

p

(mm)

0,2-1,5

0,2-0,5

-

-

-

-

-

M40 PVST

f

z

(mm)

a

p

(mm)

-

0,2-1

0,2-0,5

-

-

0,2-0,8

0,2-0,5

-

Material

steel

stainless steel

cast iron

non-ferrous

materials

high-temperature

alloys

hardened steel

Quality

Coating

Application

HSC 05 PVTi

roughing

pre finishing

finishing

-

-

100

150

200

150

225

300

-

-

-

100

175

250

35

143

250

-

P40 PVTi

roughing

pre finishing

finishing

100

160

220

100

175

250

-

-

-

-

-

-

M40 PVST

roughing

pre finishing

finishing

-

80

130

180

100

155

210

-

-

-

30

55

80

40

65

90

-

-

Feed per tooth (fz) | d.o.c. (ap)

Cutting speed (Vc in m/min)

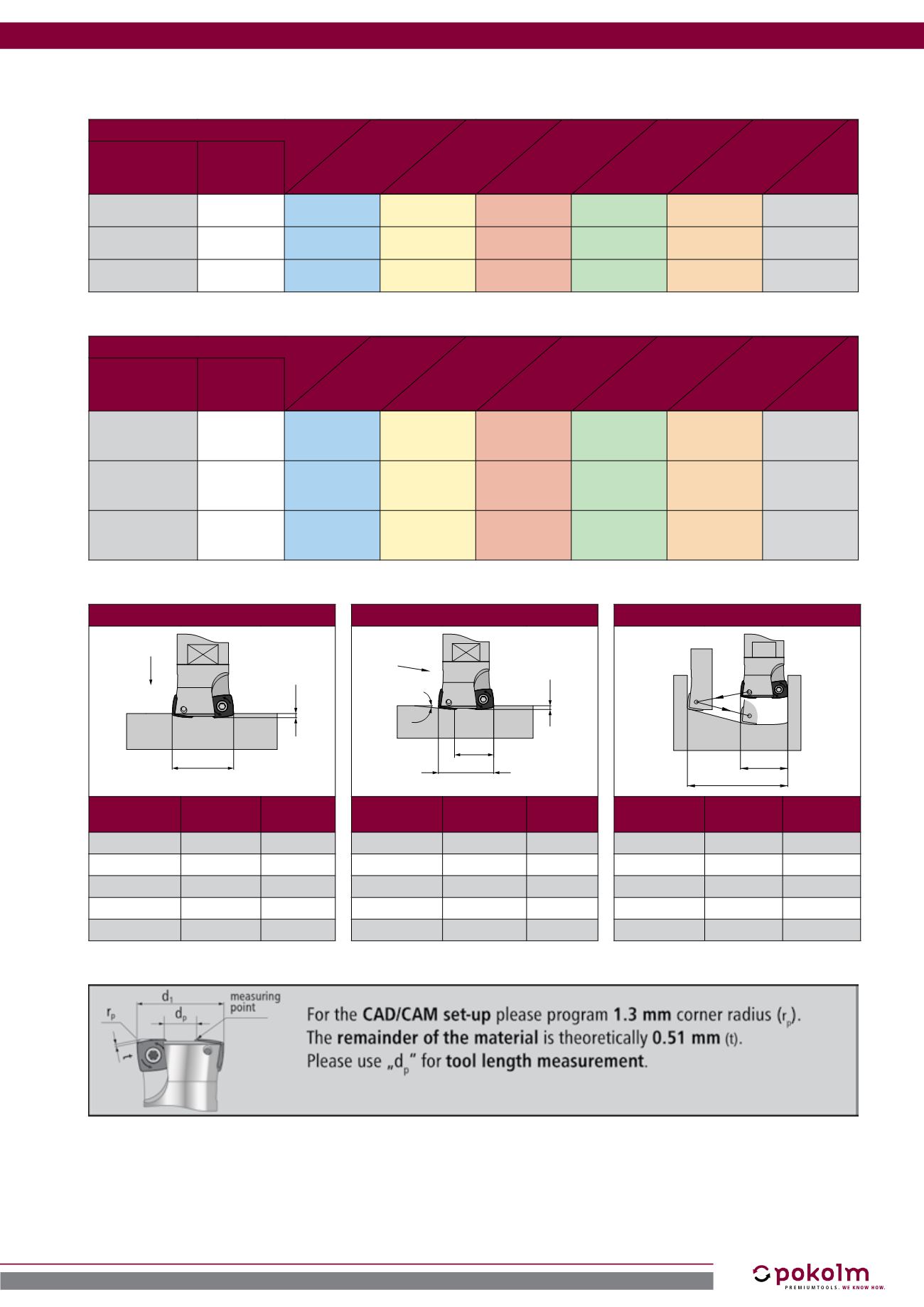

Extended operation data

Ramping

Y

d

1

X

α

Cutter diam.

d1

α

°

y

14

<13,5

4

16

<8,8

6

18

<6,6

8

20

<5,2

10

25

<3,3

15

Helix

D min/max

d

1

Cutter diam.

d1

D

min

D

max

14

18

28

16

22

32

18

26

36

20

30

40

25

40

50

Plunging

d

1

X

Cutter diam.

d1

D

p

X

max

14

3.7

1

16

5.7

1

18

7.7

1

20

9.7

1

25

14.8

1

169