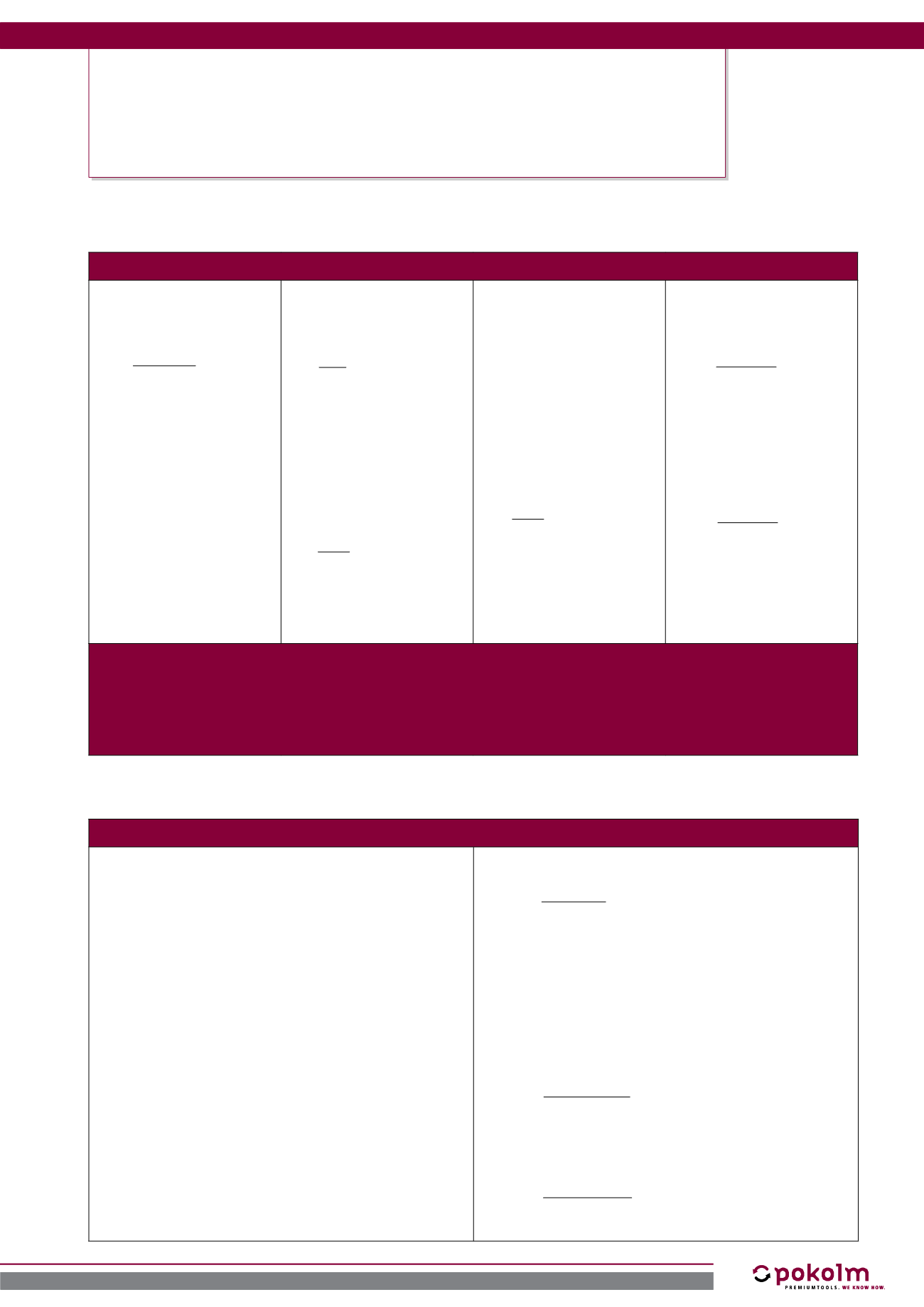

n = V

c

· 1000

π

· D

c/eff

f

z

=

V

f

n · z

V

f

= n · z · f

z

P =

a

e

· a

p

· V

f

18000

V

c

=

π

· D

c/eff

· n

1000

f

n

= z · f

z

f

n

=

V

f

n

T = I

f

V

f

Q = a

e

· a

p

· V

f

1000

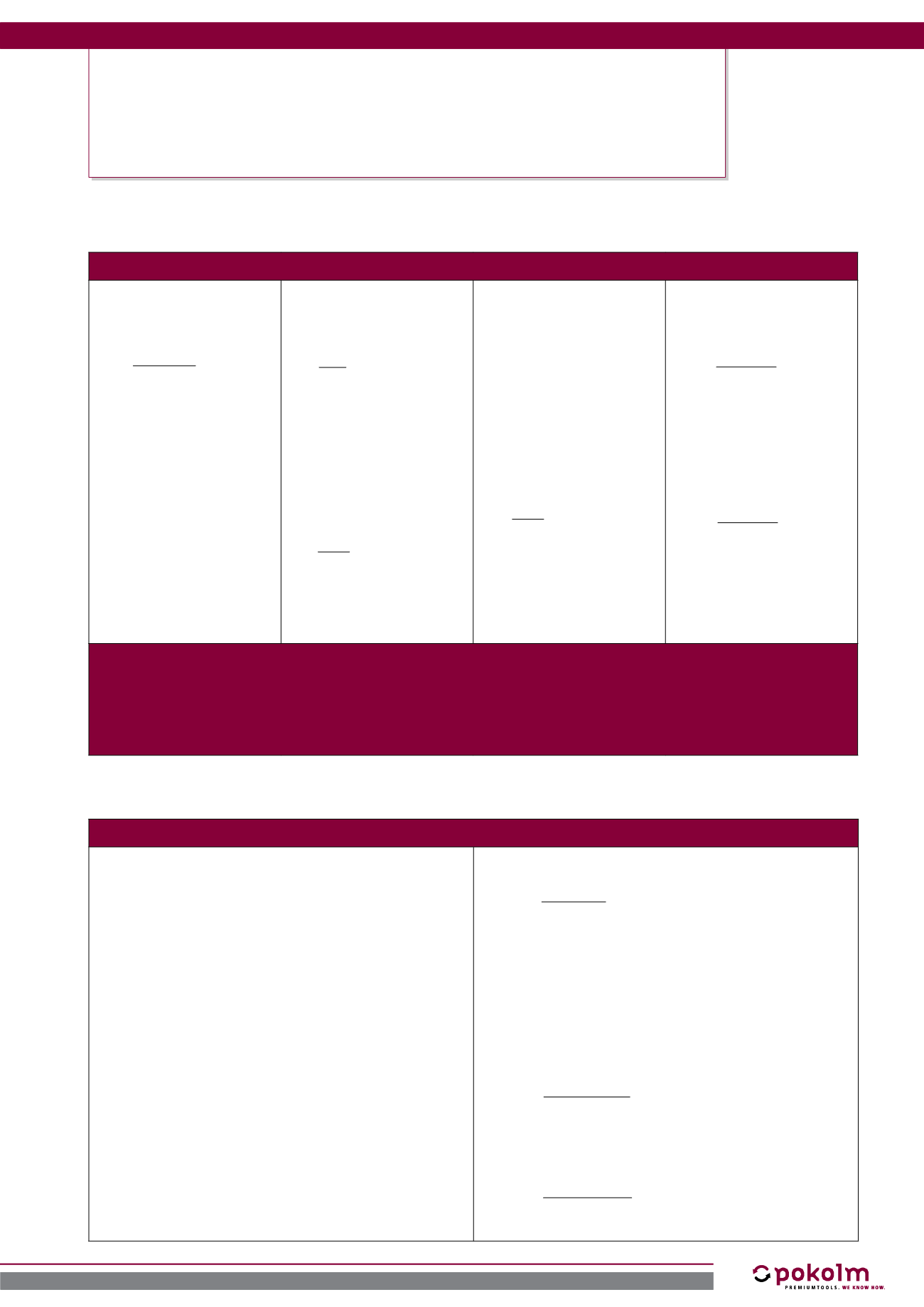

n =

250

·

1000

= 2275 U/min

π

·

35

V

f

=

2275

·

3

·

0,6

= 4095 mm/min

Q =

(25

·

1,5

·

4095) = 154 cm

3

/min

1000

P =

(25

·

1

,

5

·

4095) = 8

,

5 kW

18000

FORMULAS AND

CALCULATION EXAMPLES

Formulas

Calculation Example

Definitions:

Calculation of revolutions of

main spindle in [min-1]:*

Calculation of feed per tooth in

[mm/tooth]:

Calculation of feed per min. in

[mm/min.]:

Calculation of power requirement

in [kW]:*

Calculation of cutting speed in [m/

min]:*

Calculation of machining time in

[min]:

Calculation of machining time in

[min]:

Calculation of chip volume in

[cm3/min]:

* Please note: For flat con-

tours use true mill diameter to

calculate cutting speed (see

Surface Finish section).

* Please note: The formula gi-

ven for calculating the power

requirement is valid for machi-

ning steel only.

width of cut [mm]

depth of cut in [mm]

cutter diameter in [mm]

true tool diameter in [mm]

feed per tooth in [mm]

milling length in [mm]

feed per revolution in [mm/U]

revolution in [rpm]

power requirement in [kW]

chip volume in [cm3/min]

machining time in [min]

cutting speed in [m/min]

feed per min. in [mm/min]

no. of effective teeth

35200

03 12 840K

(P40, PVTi coated)

Ø 12 x 3,97 mm

35 mm

3

1,5 mm

25 mm

1.1730, roughing

Vc = 250 m/min

fz = 0,6 mm

Milling cutter:

Selected insert:

(see Cutting Material p. 421)

Size of insert:

Milling cutter diam.:

no. of effective teeth:

Depth of cut:

(see Operation Data Table)

Width of cut:

Material to be machined:

Selected cutting speed:

(see Operation Data pp. 392, 393,

408)

Selected feed per tooth:

(see Operation Data pp. 394-401 +

410-417)

Calculation of revolutions

Calculation of feed per min.:

Calculation of chip volume:

Calculation of power requirement:

a

e

a

p

D

c

D

eff

f

z

l

f

f

n

n

P

Q

T

V

c

V

f

z

formulas for calculating the true mill diameter can be found in the Surface Finish selection.

215

Formulas and calculation examples